Wenzhou Jintong Complete Electrical Equipment Co., Ltd. (Jintong in short) was established in Wenzhou in 2001. With more than 20 years of experience in the manufacture and sales of SMC/BMC components and molds, Jintong has grown into a professional supplier of thermosetting composite solutions for global industrial customers.

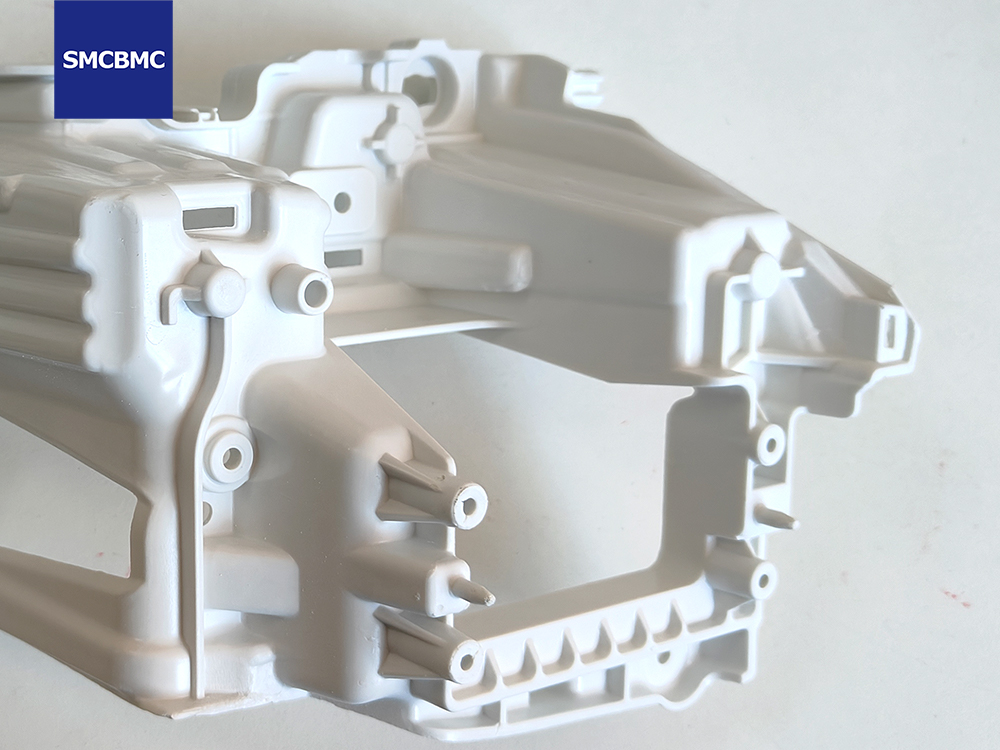

As a manufacturer specializing in thermosetting components, Jintong produces parts made from thermosetting plastics and resins, known for their high heat resistance, mechanical strength, dimensional stability, and long-term reliability. These characteristics make our products well suited for demanding applications where safety and performance are critical.

Our products are widely used across a broad range of industries, including electrical and power distribution, automotive, rail transportation, renewable energy (wind and power generation), industrial equipment, meters and instrumentation, medical devices, and other high-end industrial applications.

Over the years, Jintong has built long-term cooperation with well-known domestic and international customers, supporting them with stable quality, customized solutions, and reliable delivery. We place strong emphasis on engineering collaboration, working closely with customers from early design stages through mass production.

Jintong’s engineering team continues to develop high-performance products for electrical applications. Our product range includes fuses, disconnectors, MCCBs, micro switches, rail contactors, explosion-proof components, and related assemblies. In addition to standard products, we have designed and developed hundreds of non-standard components tailored to specific customer requirements.

The main production facility covers an area of 10,800 m², integrating in-house mold manufacturing, compression molding, and injection molding workshops. Equipped with multiple automated production lines and advanced processing equipment, Jintong maintains sufficient capacity to support both medium- and high-volume production programs.

To ensure consistent quality and sustainable operations, Jintong operates under internationally recognized management systems and has obtained ISO 9001:2015 (Quality Management System), ISO 14001:2015 (Environmental Management System), and ISO 45001:2018 (Occupational Health and Safety Management System) certifications.

Company aim: To be a global leading thermosetting corporation.

We aim to provide our employees with a comfortable and supportive working environment, along with a competitive and rewarding compensation structure.

At the same time, we are committed to becoming one of the most competitive and technologically driven companies in the automation and information-oriented segment of the thermosetting industry.

Our mission is to provide customers with complete thermosetting solutions and professional technical support, covering raw material selection, mold manufacturing, and component molding.

We focus on continuous improvement within our core expertise, learning from both growth and challenges along the way. Looking ahead, we aim to transform into an automation- and information-driven enterprise in the thermosetting industry.