Date | 2026-02-03 07:42:29

In electrical equipment, motors, rail systems, and energy infrastructure, product failure rarely begins with catastrophic events.

More often, it starts with something far less visible — dimensional drift.

A connector that no longer fits precisely.

An insulation part that loosens after thermal cycling.

A housing that warps just enough to compromise sealing or creepage distance.

While strength, flame retardancy, and insulation performance are frequently discussed, dimensional stability is the silent performance factor that defines long-term reliability. This is where BMC (Bulk Molding Compound) demonstrates a decisive advantage over many conventional plastics and even some metal solutions.

Modern electrical and industrial systems are becoming:

More compact

More integrated

More sensitive to tolerances

In applications such as:

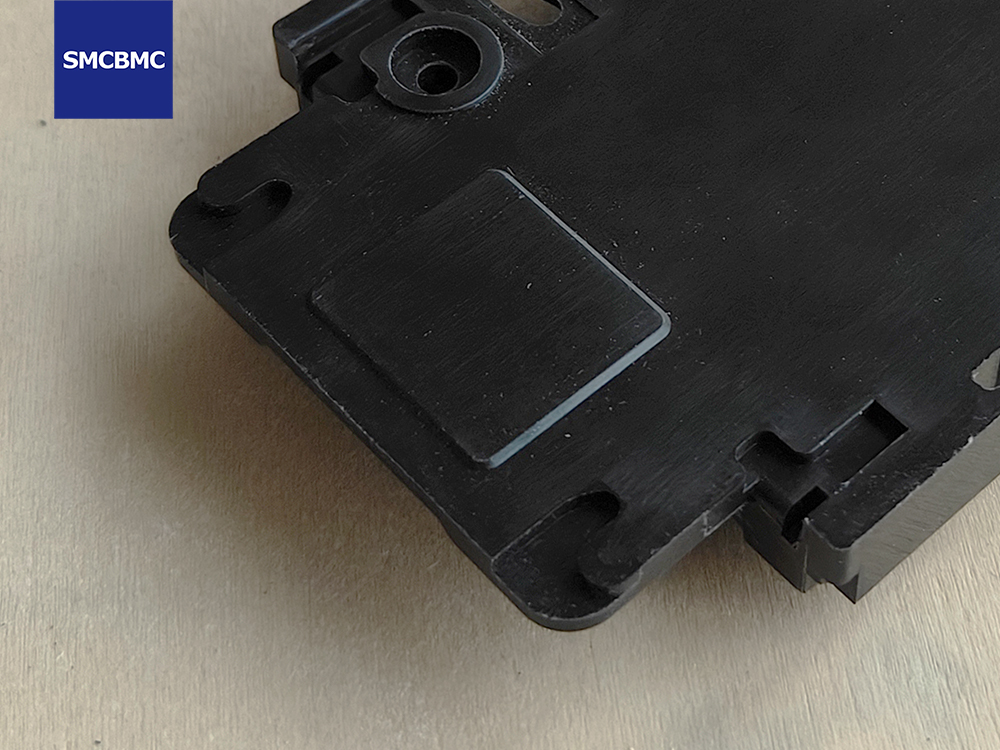

MCB and switchgear housings

Motor terminal boards and insulation pillars

Busbar supports and electrical enclosures

Rail transit electrical structures

even minor dimensional changes can result in:

Loss of mechanical preload

Increased contact resistance

Reduced creepage and clearance distances

Accelerated aging under thermal or vibration stress

Dimensional stability is not just a geometric issue — it is a system safety issue.

Unlike thermoplastics, BMC is a thermosetting composite reinforced with glass fibers and mineral fillers. Once cured, its molecular structure does not remelt or relax under heat.

Key contributors to BMC dimensional stability include:

BMC exhibits a significantly lower coefficient of thermal expansion (CTE) compared with most engineering plastics, allowing it to maintain geometry across wide temperature ranges.

In long-term mechanical loading scenarios, BMC resists deformation far better than thermoplastics, especially at elevated temperatures.

Through formulation and molding control, BMC shrinkage can be tightly managed, resulting in:

Predictable mold compensation

Excellent repeatability between batches

Unlike hygroscopic plastics, BMC absorbs minimal moisture, preventing swelling or dimensional drift in humid environments.

In transformer spacers, busbar supports, and motor insulation parts, dimensional stability ensures:

Constant electrical clearances

Secure assembly over decades of service

For terminal boards and structural motor components, stable geometry maintains:

Tight electrical connections

Reduced vibration and noise

Improved operational lifespan

In enclosures, cable management systems, and rail applications, BMC maintains dimensional accuracy despite:

Temperature cycling

UV exposure

Long-term mechanical stress

Dimensional stability is not guaranteed by material selection alone. It is the result of controlled interaction between material, mold, and process.

At Wenzhou Jintong, dimensional stability is engineered through:

Application-specific BMC formulations

Mold designs optimized for fiber flow and shrinkage balance

Precise control of mold temperature uniformity

Optimized pressure and curing profiles

This integrated approach ensures that laboratory material properties translate into real-world production consistency.

For manufacturers, dimensional stability delivers tangible value:

Reduced assembly variation

Lower rejection and rework rates

Improved field reliability

Simplified quality control

Longer product service life

In many cases, the most reliable product is not the strongest or the most flame-resistant — but the one that stays exactly where it was designed to be.

As systems become more compact and performance margins tighten, dimensional stability will continue to separate commodity materials from true engineering solutions.

BMC is not just a replacement for metal or plastics —

it is a material designed for consistency over time.

Wenzhou Jintong Complete Electrical Co., Ltd. specializes in high-performance BMC/SMC thermosetting composites, precision mold design, and compression molding of critical electrical and structural components.

We support customers in electrical insulation, motors, rail transit, new energy, and industrial equipment with dimensionally stable, high-reliability composite solutions.