Date | 2026-01-22 10:27:42

In low-voltage electrical systems, Miniature Circuit Breakers (MCBs) are the final safety barrier protecting people and equipment. While electrical ratings often receive the most attention, the housing material plays a critical and sometimes underestimated role in overall system safety.

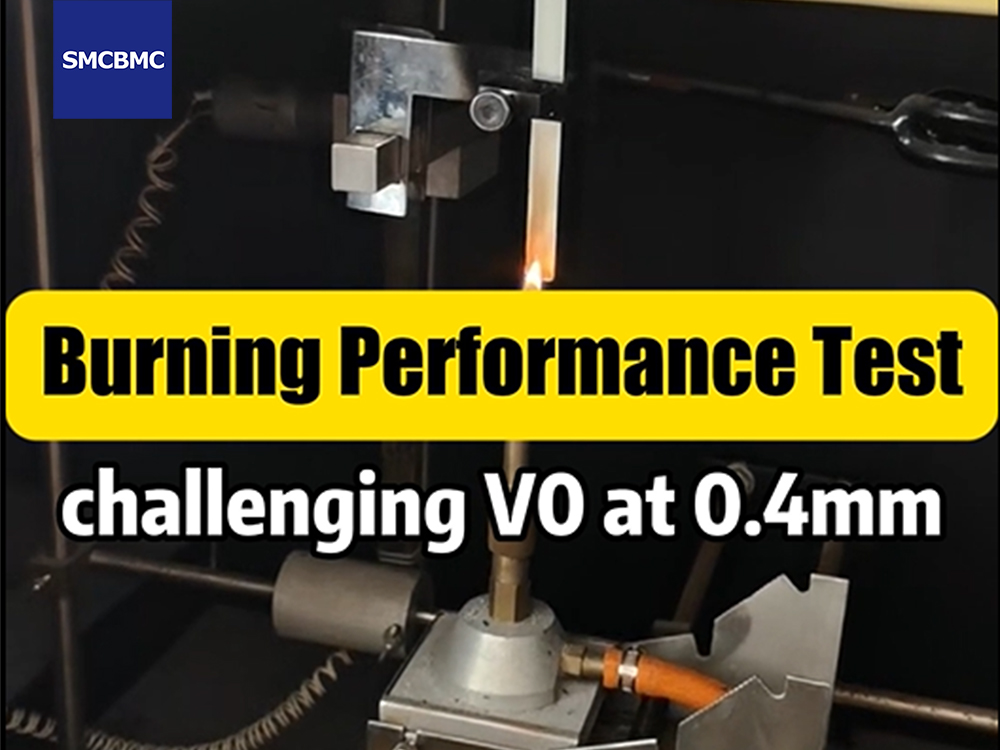

For years, UL94 V-0 has been considered a sufficient benchmark for flame retardancy. However, as MCBs become smaller, thinner, and more compact, a new question is emerging among engineers and certification bodies:

Is V-0 at standard thickness really enough?

The answer increasingly points to thin-wall performance, especially at 0.4 mm thickness, where material behavior changes dramatically.

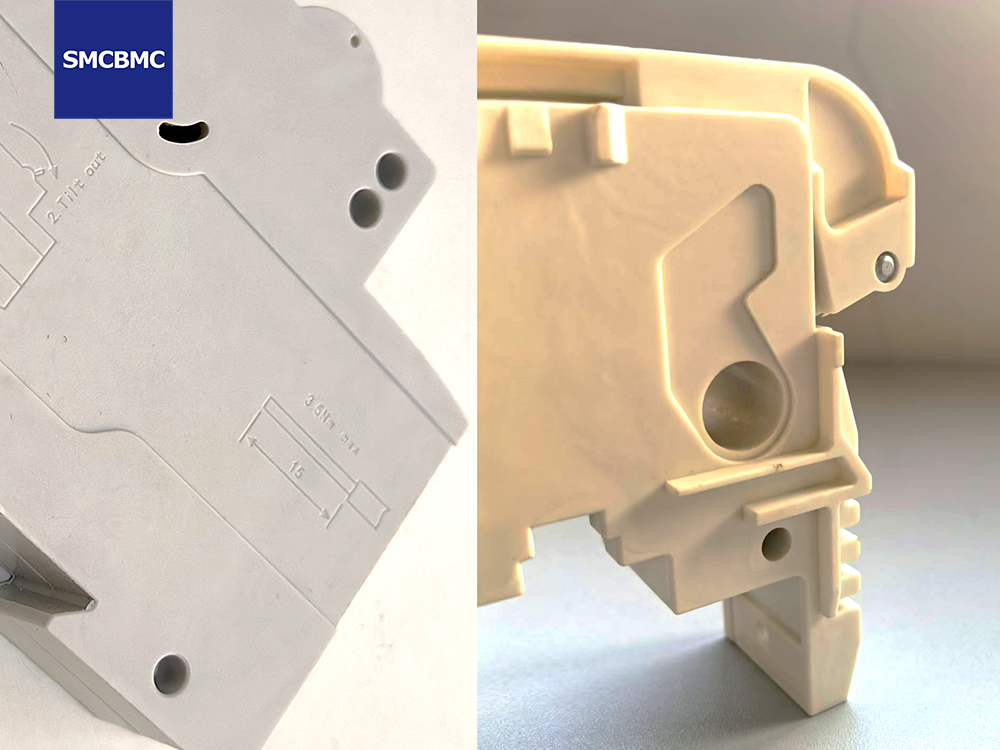

Modern MCB housings are driven by three trends:

Compact panel layouts

Higher component density

Reduced wall thickness for weight and cost optimization

In real-world designs, many internal partitions, arc chambers, and structural ribs are well below 1.0 mm, with 0.4–0.6 mm becoming common in critical zones.

At this thickness, flame-retardant performance is no longer theoretical—it is decisive.

Passing UL94 V-0 at standard thickness does not guarantee safety under thin-wall conditions.

At 0.4 mm, materials are pushed to their limits:

Heat accumulates faster

Structural integrity weakens

Melt flow, dripping, and deformation become more likely

This is where material chemistry, not just additives, determines the outcome.

Many flame-retardant thermoplastics rely on additive-based systems. Under intense heat, they may:

Soften or melt

Produce flaming drips

Lose dimensional stability

Even if the flame self-extinguishes, mechanical collapse can expose live parts or allow arc propagation.

Bulk Molding Compound (BMC) is a thermosetting composite, not a melt-process plastic. Its behavior under fire is fundamentally different.

At 0.4 mm thickness, properly formulated BMC demonstrates:

No melting, no dripping

Controlled surface charring instead of collapse

Structural integrity maintained during flame exposure

Effective arc containment

In recent flame-retardancy tests, BMC housings successfully passed UL94 V-0 at 0.4 mm, confirming stable performance under extreme thin-wall conditions.

This is not an incremental improvement—it is a qualitative safety difference.

In MCB applications, flame resistance is not just about stopping fire—it is about controlling failure.

At thin walls, material failure can lead to:

Internal arc exposure

Insulation breakdown

Secondary ignition of adjacent components

By maintaining shape and insulation during a fire event, thermosetting materials provide a critical safety margin that thermoplastics often cannot guarantee at reduced thickness.

Standards define minimum requirements, but engineering responsibility goes further.

As electrical systems become more compact, thin-wall flame performance is becoming a decisive selection criterion—not a marketing claim.

For MCB housings, V-0 at 0.4 mm represents:

Realistic worst-case conditions

True material capability

A higher level of electrical safety assurance

With over 20 years of experience in BMC materials, precision tooling, and compression molding, Wenzhou Jintong provides integrated solutions for critical electrical insulation components.

Our BMC materials are engineered specifically for:

Thin-wall flame retardancy

Arc resistance and electrical insulation

Dimensional stability under thermal stress

From material formulation to mold design and mass production, we help customers design MCB housings that remain safe when it matters most.

It is defined by performance under the harshest conditions.**

Tel: +86 13868305300

Email: wendy.qiu@smcbmc.com