Wenzhou Jintong Complete Appliances Co., Ltd. (Jintong in short) was established in Wenzhou in 2001. More than 20 years of experience in Manufacture and Sales of SMCBMC components and molds.

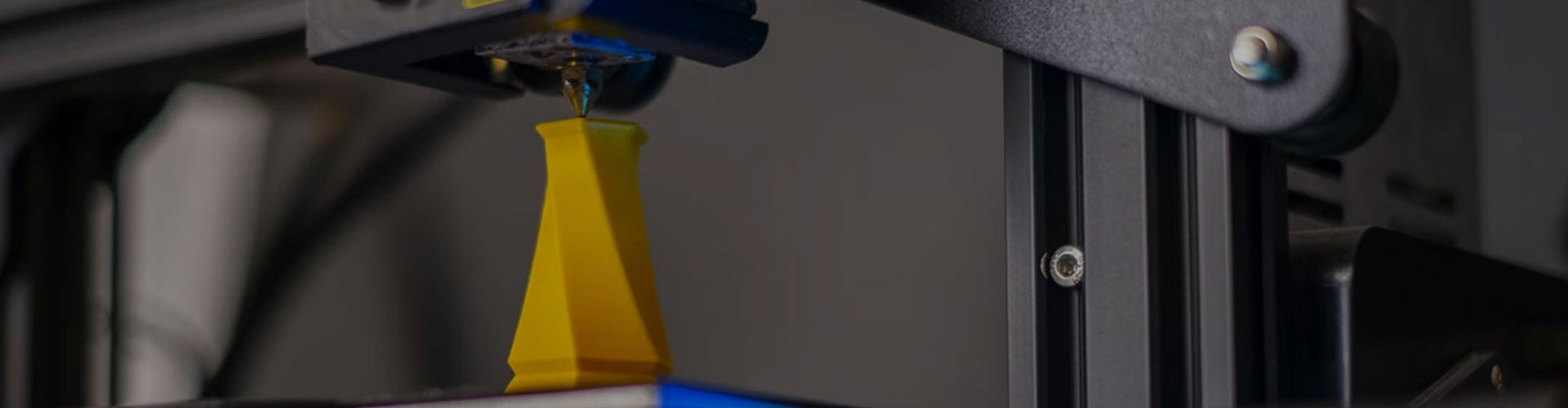

As a manufacturer of thermosetting components, Jintong specialize in producing components made from thermosetting plastics or resins. These materials are known for their high heat resistance, durability, and ability to retain their shape after molding. The finished product is often used in applications that require high strength, such as electrical and automotive components, meters, aerospace, medical, railway, electric power, wind power and other high end industries.

Jintong's team is constantly developing high performance products in electric area so far. The product range includes fuse, disconnector, MCCB, Micro switch, rail contactor, explosion etc.. Over the years , we have designed and developed hundreds of non standard products according to customer requirements.

The main production line covers an area of 10,800 m², including mold manufacturing and compression/injection molding workshops, as well as multiple automatic production lines and equipment have sufficient production capacity . Jintong have passed certificates such as : ISO 9001 : 2015 quality system certification, ISO 14001 : 2015 quality system certification, ISO 45001 : 2018 quality system certification.

Company aim: To be a global leading thermosetting corporation

We aim to provide employees with a comfortable working environment and a relatively high level salary, as well as to become the most competitive company of automation and informative among thermosetting industry.

To provide clients completely thermosetting solutions & professional technical support and services, from raw material selection, mold manufacturing, part molding, etc.. We insist on refining in the familiar field and reap the fun in the growth and failure. In the future, we will transform into an automation and information company in the thermosetting industry.

Our vision:To be a global leading thermosetting corporation.

Our goal:To be most competitive company in the thermosetting industry

SMCBMC brand becomes a world brand in thermoset industry