Jintong have specialized in thermosetting’s mold design and manufacture for years. Company regularly make compression mold and injection mold, capable with automatic pour-cutting, cold-runner, runner less technology etc..

SMCBMC offers full service support during product design. And provides system mold design to optimize design at a cost that is competitive in the marketplace and ensures long-term performance of your product.SMCBMC tool engineering team can design a custom part to meet demanding and hostile environments and provide for parts consolidation and function with molded-in inserts and eliminate secondary processing.1

Parts information:

Receive drawings and parts, communicate with customer product requirements and determine raw materials.Determine the molding method of the product.

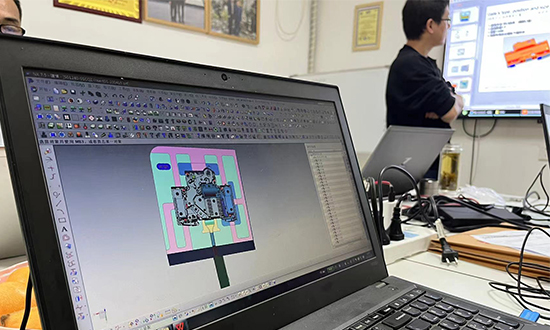

Design:

Develop a design for the mold using computer-aided design software.Pro/E & Solid Works, 3D, CAD,Capable to read DWG, DXF, IGES, S&P, STL files

Material Selection:

Based on the required raw material and properties of the product, such as strength, durability and heat resistance, choose the right steel for the mold

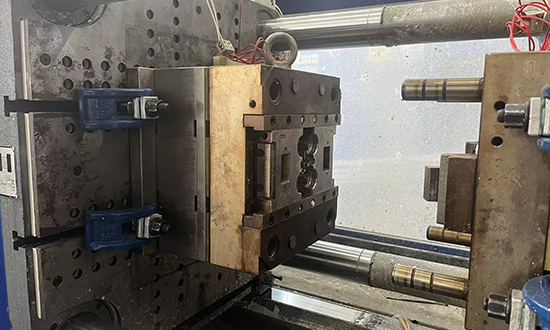

Numerical control machining

SMCBMC use the world's most advanced processing equipment for wire cutting, electrical pulse, finishing and other steps, so as to ensure the performance and accuracy of the mold.Almost all tools of the processing resources.

Polishing

Smooth and polish the surface of the mold to ensure proper functionality and a smooth finish for the end product.

Recheck

Conduct tests to verify the accuracy and functionality of the mold, such as pressure testing,dimension and thermal cycling tests.

Assembly

Assemble the different components of the mold, such as the core and cavity, to create the complete mold.

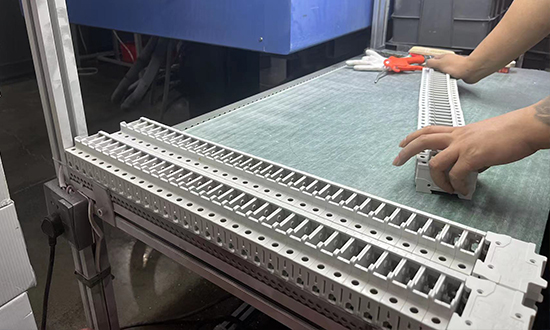

Quality Control

Inspect the mold to ensure it meets the design specifications and is free of defects.