Date | 2021-06-17 15:32:53

A large number of molding compounds of bmc products have excellent electrical equipment performance, mechanical equipment performance, heat resistance and solvent erosion resistance, and can meet the performance requirements of various products, so they are increasingly favored by customers.

Overall molding compound (bmc product) is a kind of thermosetting plastic plastic, in which various inert fillers, chemical fiber to improve raw materials, metal catalysts, thickeners and color pastes are mixed to produce a kind of adhesive "grease-stain-like" polymer Shrink molding or injection molding of materials. Small pieces of molding compound (bmc products) are filled and improved by polyester staple fiber aspect ratio, glass fiber increases the raw material occupies 10 to 30 points, and the length is generally between 1/32 inch to 1/2 inch (12.5mm) .

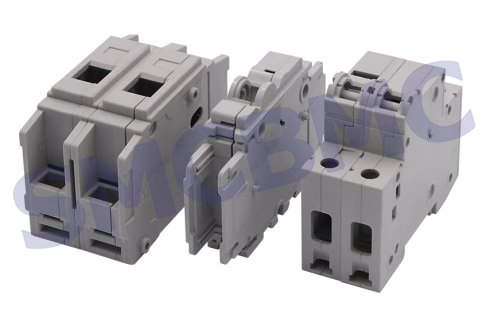

According to different final main applications, the prepared polymer materials can be jingque controlled specifications, with excellent flame retardant grade and tracking resistance, high volume resistivity, corrosion resistance and stain resistance, excellent structural mechanics Performance, low shrinkage, stable color tone. Small block molding compound (bmc product) has excellent circulation, dielectric strength and flame retardant grade, which is especially suitable for various applications where key points and specifications must be jingque. There are 75 colors to choose from, which can be used for electrostatic powder spraying or water-based coating.

of course:

Based on the granular prepreg produced by mixing chopped glass fiber and unsaturated polyester slurry. Suitable for molding, transfer molding, injection molding, etc. The products produced have excellent mechanical equipment performance, high specification reliability, excellent surface smoothness, excellent wear resistance, wear resistance, corrosion resistance, heat resistance and excellent electrical equipment performance, especially electrical resistance Solitary can reach up to 190 seconds

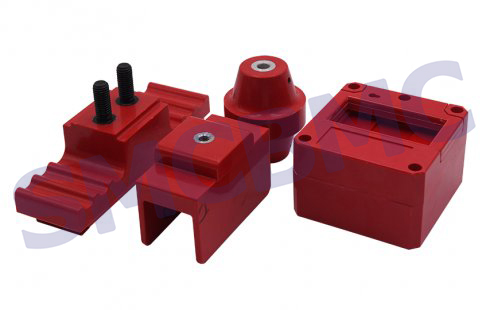

1. General performance: The ratio of bmc products is 1.3-2.1; the product has a bright appearance, good touch, and has a hard and heavy feel; heating with fire will cause a lot of kitchen fumes and a taste of butadiene; some types The bmc products (DMC) cannot be ignited, but some types are very easy to ignite, leaving inorganic compounds after ignition.

2. Specification reliability: The thermal expansion coefficient of bmc products (DMC) is (1.3-3.5) 10-5K-1, which is lower than general thermosetting plastics, so bmc products (DMC) have high specification reliability and specification precision . Temperature has little harm to the reliability of the specifications of bmc products, but the environmental humidity is more harmful and will swell after digestion and absorption of water. The thermal expansion coefficient of the prefabricated overall molded plastic product is close to steel and aluminum, so it can be composited with the prefabricated overall molded plastic product.

3. Impact toughness: The tensile strength, bending strength and impact compressive strength of bmc products are higher than thermosetting plastics, and the stress relaxation resistance is also better than thermosetting plastics.

4. Wear resistance and washing resistance: bmc products (DMC) have excellent corrosion resistance to water, alcohol, aliphatic hydrocarbons, vegetable fats and oils, but not to ketones, chlorinated hydrocarbons, aliphatic hydrocarbons, acids and alkalis, etc. With corrosion resistance. Bmc products (DMC) have low water absorption, and the thermal insulation performance is still excellent after soaking for one day.

5. Heat resistance: bmc products (DMC) have stronger heat resistance than general engineering plastics. The heat distortion temperature HDT is 200-280, and it can be used for a long time under 130.

6. Kanglaohua: bmc products (DMC) have excellent kanglaohua, can be used in the room for 15-20 years, and the compressive strength maintenance rate exceeds 60 points after 10 years of outdoor exposure.

7. Electrical equipment performance: bmc products (DMC) have zuituchu anti-isolation, which can reach up to 190 seconds.

8. Low taste: The butadiene coupling agent used for bmc products (DMC) still has 0.1 point residue after drying, and will release the taste when heated. Therefore, bmc products (DMC) used for food products (such as microwave heating kitchenware) should use UP epoxy resin without residual butadiene alone.