Date | 2025-12-29 08:07:21

In thermoset injection mold design, runner sizing is one of the most critical factors affecting molding stability, part quality, and production efficiency.

Unlike thermoplastics, thermoset materials such as BMC, phenolic, and epoxy undergo an irreversible chemical crosslinking reaction under heat and pressure.

If premature curing occurs inside the runner system, it may lead to short shots, blocked runners, unstable filling, or even mold damage.

Therefore, runner design for thermoset injection molds follows a fundamentally different logic compared with thermoplastic molding.

From a material behavior perspective:

Thermoplastics:

Melt when heated and solidify when cooled

→ Runner design focuses on heat retention and preventing premature cooling

Thermoset materials (BMC, phenolic, epoxy):

Flow briefly after heating, then cure irreversibly at elevated temperature

→ Runner design must prevent premature curing and minimize material residence time

Core design principle for thermoset runners:

Ensure fast and complete cavity filling

while keeping the runner cross-section as small as possible

to reduce material retention and waste.

There is no universal formula for thermoset runner sizing.

In practice, runner design is an iterative process that starts with experience-based estimation and is refined through adjustment and validation.

Main runner diameter is typically 0.5–1.0 mm larger than the injection nozzle diameter

Taper angle: 2°–3°

The outlet diameter of the main runner serves as the reference for sub-runner sizing

A commonly used empirical formula is:

D = k × √W

Where:

D = sub-runner diameter (mm)

W = total material weight flowing through the runner (g)

k = empirical coefficient (typically 3.5–5.5)

Recommended values:

Good flowability / slower curing: k = 3.5–4.5

Poor flowability / faster curing: k = 4.5–5.5

This calculation provides a safe starting point, not the final dimension.

Thermoset materials vary significantly in formulation.

Fillers, fiber type, and resin chemistry strongly affect flow behavior.

Therefore, more reliable references include:

Material supplier recommended runner dimensions

Proven industry experience

Typical reference ranges (for design guidance only):

| Item | Recommended Range |

|---|---|

| Main runner diameter | 5–12 mm |

| Sub-runner diameter | 4–10 mm |

| Small parts (<50 g) | 4–6 mm |

| Medium parts (50–200 g) | 6–8 mm |

| Large parts | 8–10 mm |

| Gate size | 50%–80% of part wall thickness |

Material supplier data should always take priority.

After initial sizing, further adjustment is required based on:

Runner length

Longer runners cause higher pressure loss → diameter should be increased

Part wall thickness

Thinner walls increase filling resistance → larger runner diameter required

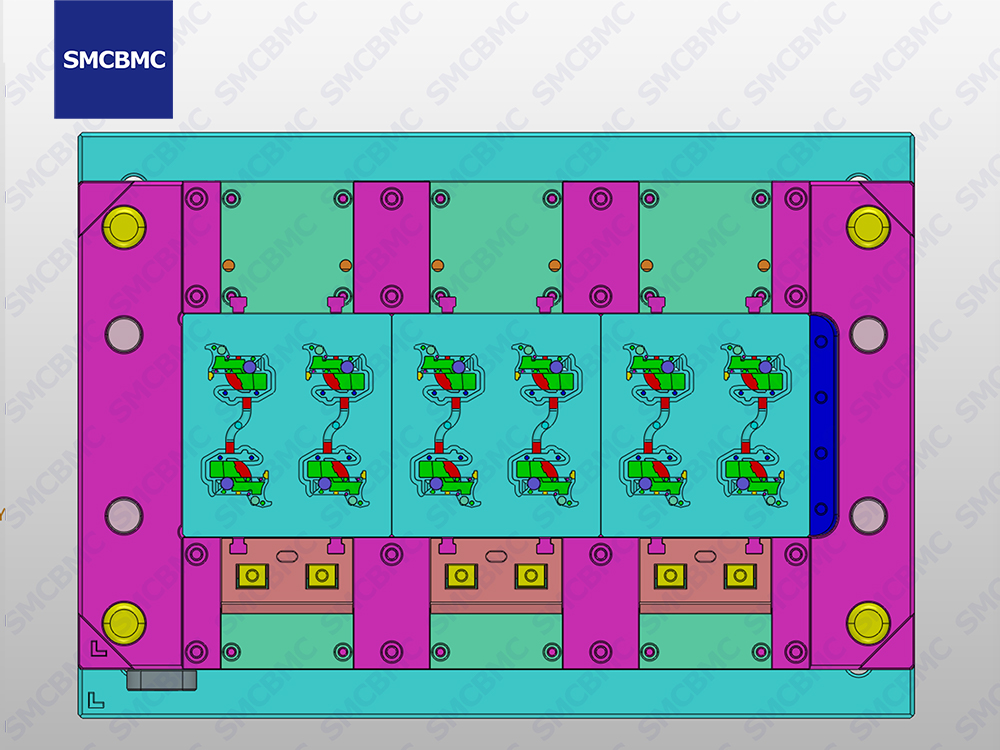

Number of cavities and layout

Multi-cavity molds require runner balancing

(equal filling time via diameter or length adjustment)

Prevention of premature curing

Oversized runners → excessive residence time and early curing

Undersized runners → rapid surface curing and restricted flow

Typical mold temperature: 160–190°C, balance is critical

Cross-section shape

Full round runners are optimal

Lowest flow resistance and minimal heat loss

Surface finish

High polishing (mirror finish) is essential

Reduces material adhesion and improves ejection of cured runner material

Obtain material supplier runner recommendations

Calculate initial dimensions using empirical formula

Adjust based on part weight, wall thickness, and cavity layout

Perform mold flow analysis if possible

Design critical runners as replaceable inserts for easy trial modification

Runner sizing for thermoset injection molds is not a single calculation,

but a systematic engineering process involving material behavior, mold structure, and molding conditions.

Experience, material knowledge, and tooling expertise must work together to achieve stable and repeatable production.

Wenzhou Jintong Complete Appliances Co., Ltd. specializes in BMC/SMC materials, thermoset mold design, and molding manufacturing.

With extensive experience in electrical, rail transportation, and industrial applications, we provide integrated solutions from material selection and runner design to molding validation and mass production.

If you are developing BMC or other thermoset injection molds, feel free to contact us for technical discussion and support.