Date | 2026-01-04 12:54:19

In manufacturing—especially in the demanding field of thermoset composite molding such as BMC and SMC—the statement “the mold is the product” is far from an exaggeration.

The quality of mold design directly determines the dimensional accuracy, mechanical performance, surface appearance, and overall production cost of the final part.

A well-designed mold is the critical bridge between innovative product design and stable, high-volume manufacturing.

High-level mold design is a systematic engineering discipline that integrates material science, mechanical engineering, fluid dynamics, and process experience.

Its core objective is clear:

to meet functional requirements while ensuring efficient production, consistent quality, and controllable cost.

This requires addressing several key challenges.

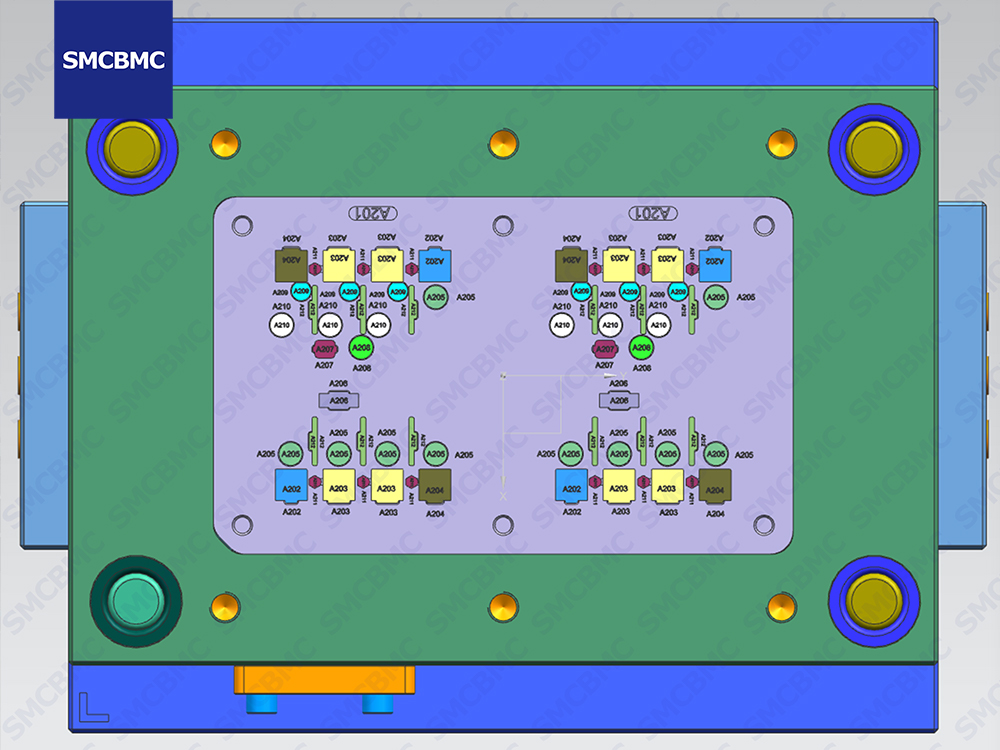

Cavity accuracy is the foundation of dimensional tolerance control. Designers must comprehensively consider:

Material shrinkage behavior

Draft angles (typically ≥5° on the moving side and ≥3° on the fixed side)

Parting line selection

Ejection system layout

For example, reinforcement ribs should generally maintain a height-to-thickness ratio ≤3, with sufficient fillet radius at the root (≥0.5 mm) to ensure smooth material flow and avoid stress concentration.

For thermoset injection or transfer molding, runner design is critical to preventing premature curing.

Key considerations include:

Main runners equipped with cold slug wells

Sub-runners designed with full-round cross-sections to minimize heat accumulation

Runner dimensions precisely calculated based on material flow behavior and part weight

(commonly using the empirical formula D = k√W)

Balanced filling across all cavities to ensure synchronized flow

During curing, thermoset materials release gases. Vent design must therefore be precise:

Typical vent depth: 0.01–0.03 mm

Vent locations positioned at the end of flow paths

Equally important is the mold’s heating and cooling system.

Uniform cavity surface temperature—typically controlled within ±5°C—is essential to ensure consistent curing and prevent warpage or deformation.

Mold durability and economic efficiency depend on:

Proper steel selection (e.g., pre-hardened steel or H13 for cores)

Surface treatments such as nitriding or hard chrome plating

(surface hardness ≥ 58 HRC)

Use of standardized components

Modular design for ease of maintenance and replacement

Together, these factors determine mold longevity and long-term production stability.

A qualified mold must pass a rigorous validation process (T0–Tn trials), including:

Critical dimensions are fully inspected using CMM measurement, ensuring compliance with drawing tolerances (e.g., ISO 2768-mK).

Under real production parameters, the mold must operate continuously for hundreds of cycles to verify:

Process stability

Demolding success rate (target ≥ 99.5%)

Flash control capability (flash thickness ≤ 0.15 mm)

Initial production samples must pass all specified performance tests, including:

Electrical strength

Flame retardancy

Mechanical performance

Only after completing this closed-loop verification can a mold be considered production-ready.

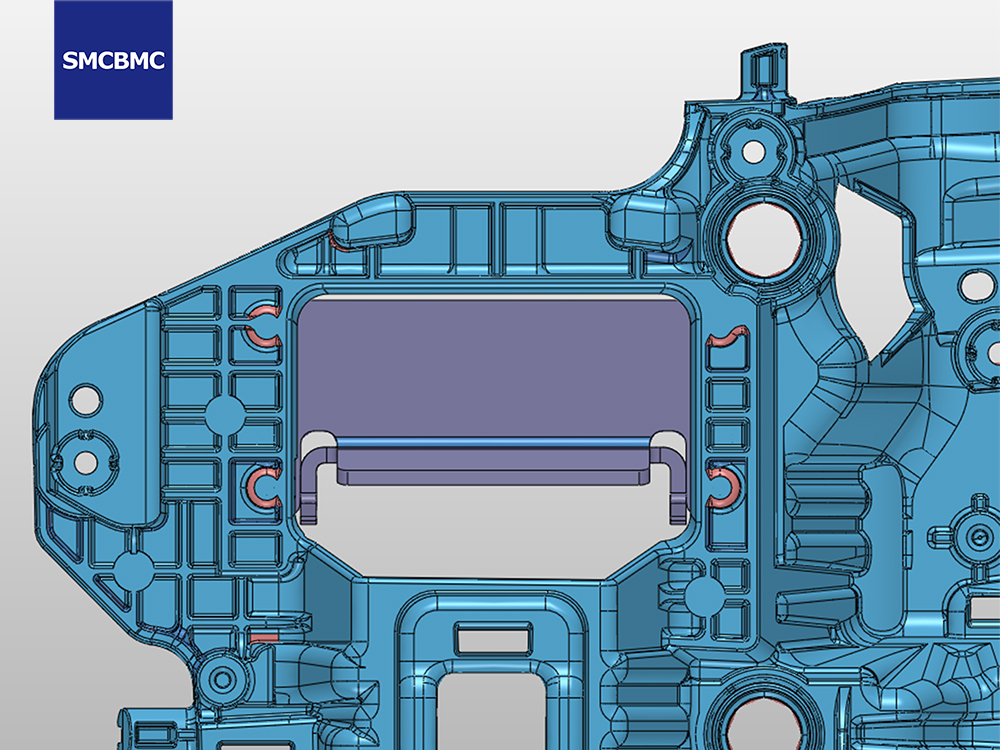

Deep expertise in mold design comes from a thorough understanding of materials and processing across the entire value chain.

With more than 20 years of experience in BMC/SMC thermoset molding, Wenzhou Jintong has developed a unique advantage:

Material application knowledge drives mold design decisions.

What we provide is not just mold manufacturing, but performance-oriented, system-level solutions:

Collaborative Design (DFM)

Early involvement to optimize product design based on material flow, shrinkage behavior, and structural requirements.

End-to-End Process Control

From 3D design and mold flow analysis to precision machining

(5-axis CNC, wire EDM, mirror-finish EDM) and trial validation.

Mass Production Support

We understand the strong linkage between tooling and molding processes and provide support in optimizing process windows to fully unlock mold potential.

We believe that an excellent mold is the starting point for product success, cost reduction, and production efficiency.

Choosing Jintong means choosing a partner who thinks like a material specialist, mold engineer, and process expert—all at once.