Date | 2026-01-06 14:31:56

In low-voltage power distribution systems, Miniature Circuit Breakers (MCBs) serve as critical guardians of end-circuit safety. However, the rigid outer protective shell—the MCB housing—is far more than a simple “plastic cover.” It plays a decisive role in electrical insulation, mechanical support, safe arc interruption, and long-term operational reliability.

As electrical equipment continues to evolve toward compact designs, higher safety requirements, and extended service life, conventional thermoplastics are increasingly unable to meet performance demands. Thermosetting composite materials, represented by BMC (Bulk Molding Compound) and SMC (Sheet Molding Compound), have become the preferred choice for high-end MCB housings due to their outstanding overall performance.

In demanding electrical environments, a qualified MCB housing must pass multiple stringent technical requirements:

MCB housings require extremely high insulation resistance (≥10¹³ Ω·cm) and excellent arc resistance (≥180 s). These properties ensure that electric arcs generated during short circuits or overloads are effectively contained and extinguished, preventing leakage currents and dielectric breakdown.

Materials must comply with strict flame-retardant standards such as UL94 V-0, maintaining structural integrity without softening, dripping, or deformation under both continuous operating temperatures and short-term abnormal heat peaks—significantly reducing fire risks.

MCB housings must protect sensitive internal trip mechanisms, requiring high rigidity and precise dimensional control. Stability must be maintained across a wide temperature range (-40°C to 125°C) and under long-term mechanical stress to ensure consistent breaking performance.

Materials should be well-suited for high-efficiency precision compression molding, enabling the integration of complex structures in a single molding cycle while ensuring batch-to-batch consistency and controlled manufacturing costs.

Through glass fiber reinforcement and specialized filler modification, BMC and SMC materials successfully integrate these seemingly conflicting requirements, providing inherent material-level reliability for MCB housings.

With over 20 years of experience in thermosetting composite materials, Wenzhou Jintong deeply understands the safety logic and performance requirements of circuit breaker products. We offer more than molded housings—we deliver a fully integrated “Material–Design–Manufacturing” solution for the electrical industry.

Based on your specific MCB housing requirements—including arc resistance, CTI (Comparative Tracking Index), glow-wire performance, and mechanical impact resistance—we tailor and optimize BMC/SMC formulations to ensure precise performance matching from the material foundation.

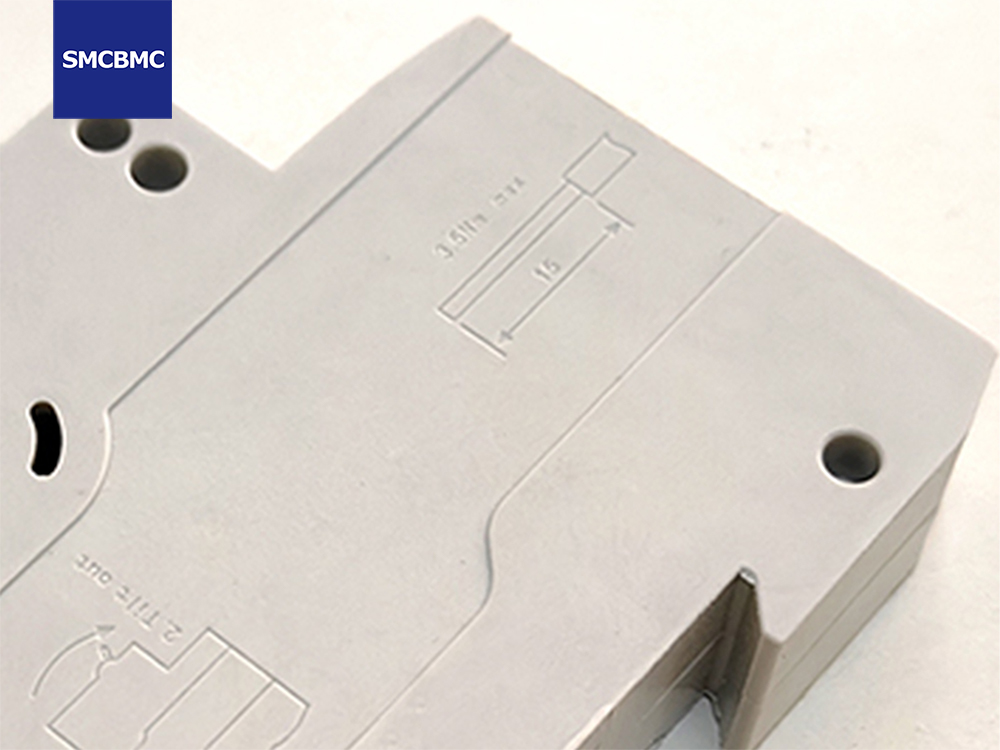

Our dedicated tooling R&D center specializes in high-precision compression mold design for MCB housings. We achieve minimal draft angles, accurate snap-fit and mounting features, uniform wall thickness, and optimized rib structures—balancing mechanical strength, insulation performance, and material efficiency.

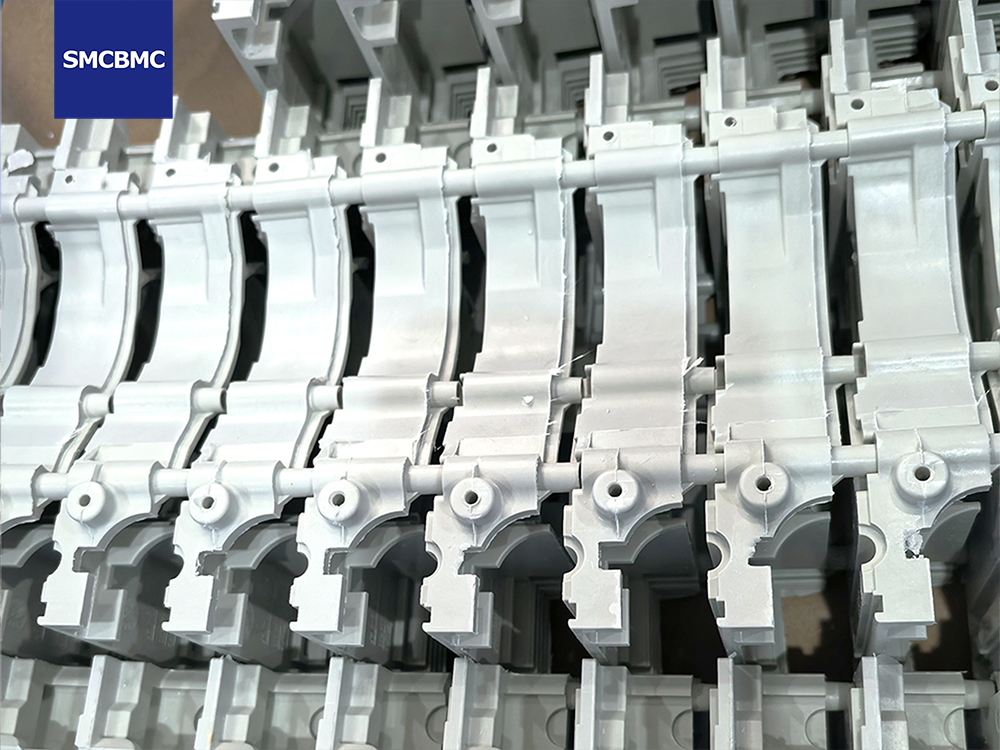

Supported by automated compression molding lines and strict process control systems compliant with internal technical standards (such as Q/JTJ0002-2025), we ensure consistent dimensional accuracy, surface quality, and internal performance across every production batch—providing long-term reliability for your products.

With proven experience serving globally recognized electrical brands, we understand the critical importance of MCB housings as key safety components. Choosing Jintong means partnering with a team that combines material science expertise with precision manufacturing craftsmanship.

If you are developing next-generation miniature or compact circuit breakers, or seeking to optimize the performance and cost of existing MCB housings, we welcome you to contact us for professional technical support and customized solutions.