Date | 2026-01-24 13:57:11

In today’s rapidly advancing electric vehicle (EV) industry, lightweighting has become a core technology to enhance range and energy efficiency. Compared to traditional metals, advanced thermosetting composites, represented by BMC (Bulk Molding Compound) and SMC (Sheet Molding Compound), are redefining the landscape of key components in new energy vehicles. These materials offer outstanding strength-to-weight ratios, excellent design freedom, and superb corrosion resistance.

At Wenzhou Jintong Complete Appliances Co., Ltd. (Jintong), we are committed to providing integrated lightweight solutions for critical components, covering everything from appearance to structure, protection to functionality. The following key components are already benefiting from our high-performance composite technology:

In this field, composites achieve complex curvatures and refined surface finishes while significantly reducing weight.

Bumpers: High toughness and elastic recovery, improving low-speed collision repair economy.

Hood and Tailgate: Achieving significant weight reduction while maintaining excellent dimensional stability.

Fenders and Mudguards: Resistant to stone impacts and corrosion, maintaining appearance over time.

Spoilers and Front Covers: Aerodynamically optimized, reducing drag and improving energy efficiency.

Detachable Hardtops: Providing lightweight, high-rigidity modular roof solutions for high-end models.

For the harsh operating environment of the chassis, composites provide solid protection and stable performance.

Underbody Shields: Fully protecting the battery pack and chassis lines, with scratch resistance, impact resistance, and chemical corrosion resistance.

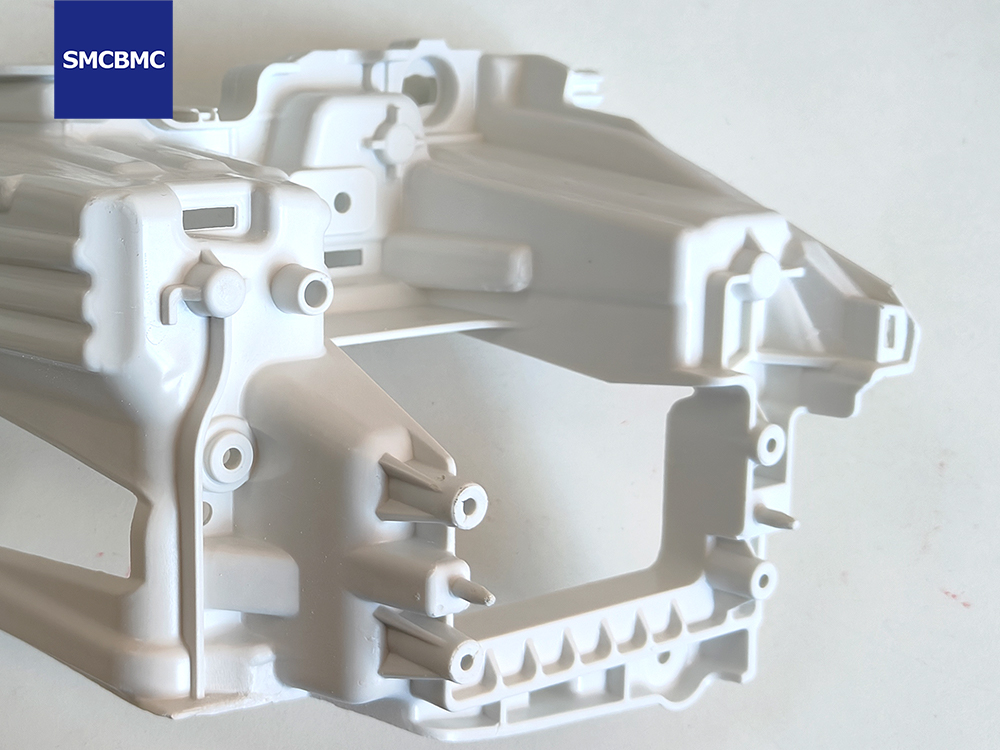

Power Battery Box (Shell/Cover): Meeting high protection levels (such as IP67), with excellent insulation, flame retardancy (up to V-0), and thermal management properties. This is a key safeguard for battery safety.

Composites showcase high precision molding and long-lasting durability in these parts.

Headlamp Housings (Especially LED Headlamps): High temperature and UV aging resistance, ensuring long-term light transmission and sealing integrity.

Sun Visors: Lightweight and robust, with the ability to integrate multiple functional modules.

Significant Lightweight Benefits: Compared to equivalent steel parts, we achieve weight reductions of up to 30%-50%, directly contributing to increased driving range.

Outstanding Comprehensive Performance: Our BMC/SMC material systems are customizable to meet specific part requirements, offering high rigidity, high impact strength, excellent heat resistance, and flame retardancy (meeting automotive safety standards). Additionally, they offer natural electrical insulation and corrosion resistance.

High Design Integration Freedom: Multiple parts can be integrated into a single module, reducing assembly steps, enhancing structural efficiency, and enabling more complex, optimized designs.

Complete Value Chain Service: We are not just a component supplier, but a full-process technology partner, providing material formulation development, structural simulation and optimization, precision mold design and manufacturing, and automated high-quality molding, ensuring reliable product realization from concept to mass production.

From the stylish dynamics of bumpers to the solid protection of power battery boxes; from optimizing aerodynamics in spoilers to every human-centric consideration in sun visors, we are deeply involved in the evolution of the new energy vehicle industry through the power of materials science.

We invite major OEMs and component partners to discuss how we can leverage high-performance composite materials to build lighter, stronger, and safer parts for the next generation of intelligent electric vehicles, driving the future of green mobility together.

Wenzhou Jintong Complete Appliances Co., Ltd. (Jintong) is a high-tech enterprise specializing in the research, development, and production of high-performance BMC/SMC thermosetting composites and molded components. We focus on providing key lightweight, high-safety, and long-life solutions for the new energy vehicle and electrical industries.