Date | 2026-01-19 08:09:09

In modern electrical, energy, and industrial equipment design, material selection is no longer a cosmetic or cost-only decision. It directly affects safety, reliability, compliance, lifecycle cost, and brand risk.

When engineers evaluate BMC (Bulk Molding Compound) versus engineering thermoplastics (such as PA, PC, PBT, PPS), the real question is not “Which material is stronger or cheaper?” but:

Which material delivers the highest system reliability under real operating conditions?

This article provides a clear decision matrix to help engineers, project managers, and product designers choose the right material based on performance logic, not assumptions.

Before comparing data, it is critical to understand the material nature.

Cross-linked polymer structure (irreversible curing)

Glass fiber reinforced

Will not melt, soften, or drip under heat

Designed for structural, electrical, and fire-critical components

Linear or branched molecular structure

Soften and melt when heated

Good for complex shapes and aesthetic parts

Performance strongly depends on temperature and time

This structural difference explains most performance gaps discussed below.

| Evaluation Criteria | BMC (Thermoset) | Engineering Plastics |

|---|---|---|

| Heat Resistance | Excellent (Tg up to 230 °C) | Moderate to good, but softening occurs |

| Flame Retardancy | Inherent, UL94 V-0 without halogens | Additives required, aging sensitive |

| Arc & Tracking Resistance | Very high (CTI ≥ 600 achievable) | Limited, degrades over time |

| Dimensional Stability | Excellent (low CTE) | Creep and deformation under load |

| Long-Term Mechanical Strength | Stable over decades | Stress relaxation and creep |

| Electrical Insulation Stability | Excellent | Sensitive to heat and humidity |

| Vibration Damping | Very good (fiber + matrix synergy) | Limited |

| Environmental Aging | UV, heat, humidity resistant | Property loss over time |

| Design Freedom | Medium–High (compression molding) | Very high (injection molding) |

| Recyclability | Limited (thermoset) | Easier (thermoplastic) |

BMC is not selected for convenience, but for risk control.

Typical applications:

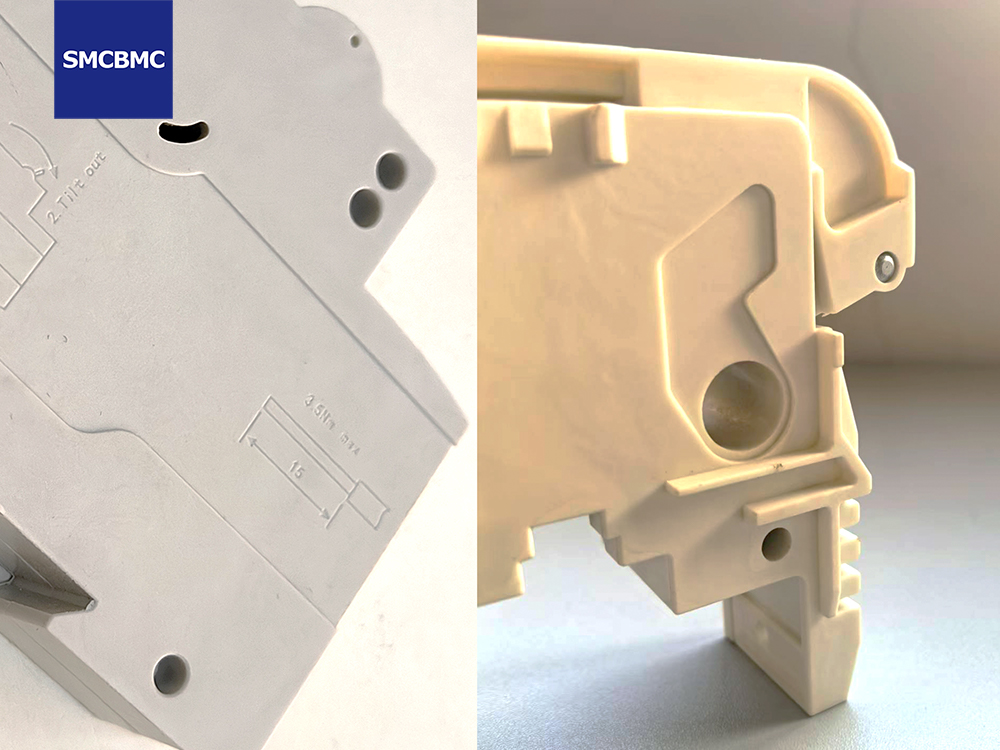

MCB housings and arc chambers

Electrical insulation supports

Motor stator encapsulation

Busbar supports and terminal blocks

High-temperature, fire-sensitive components

Why engineers choose BMC:

No melting or dripping in fault conditions

Stable dimensions under continuous heat

Predictable insulation performance over time

Higher tolerance to overload, vibration, and aging

👉 In safety-critical electrical applications, BMC is a reliability material.

Engineering plastics excel where:

Thin walls and complex geometry are required

Aesthetic surface finish is important

Operating temperature is controlled

Fire exposure risk is low

Typical applications:

Control knobs and covers

Connectors (non-arc areas)

Consumer electronics housings

👉 Engineering plastics are excellent design materials, but not failure-forgiving materials.

A frequent misconception is:

“Engineering plastics are cheaper than BMC.”

In reality:

Material cost per kg may be lower

System cost over lifecycle is often higher

Hidden costs of incorrect material choice:

Field failures

Certification challenges (UL, IEC)

Warranty claims

Brand and safety risk

BMC often delivers lower total cost of ownership (TCO) in long-life electrical products.

Use this rule during early design reviews:

If the component must still perform safely after 10–20 years of heat, current, vibration, and overload → choose BMC.

If the component prioritizes shape, appearance, and short-term performance → consider engineering plastics.

Material choice alone does not guarantee performance.

To fully unlock BMC advantages, success depends on:

Correct formulation (fiber length, filler system, resin chemistry)

Mold design adapted to material flow and curing

Stable compression molding process control

This is why material–mold–process integration is critical for high-reliability BMC components.

The real advantage of BMC is not just strength or heat resistance.

It is predictability.

In electrical and industrial systems where failure is unacceptable, thermosetting composites provide a wider safety margin than thermoplastics ever can.

Choosing between BMC and engineering plastics is not a trend decision —

it is a risk management decision.