Date | 2026-01-27 07:39:38

In the core of power transmission, industrial motors, and electrical equipment, safety and stability rely on a system of invisible, precision components—the electrical insulation system. As a reliable solutions provider in this field, Wenzhou Jintong Complete Appliances Co., Ltd. (Jintong) specializes in the use of BMC (Bulk Molding Compound) and SMC (Sheet Molding Compound) high-performance thermosetting composites to manufacture critical insulation components that safeguard the longevity and reliability of electrical systems. From transformer cushions ensuring grid safety to explosion-proof motor insulation pillars that drive industrial motors, our products provide exceptional electrical insulation, mechanical strength, heat resistance, and dimensional stability.

In high-voltage environments, the reliability of insulation components directly determines system safety. We provide core support and isolation components for the power transmission and switching sector:

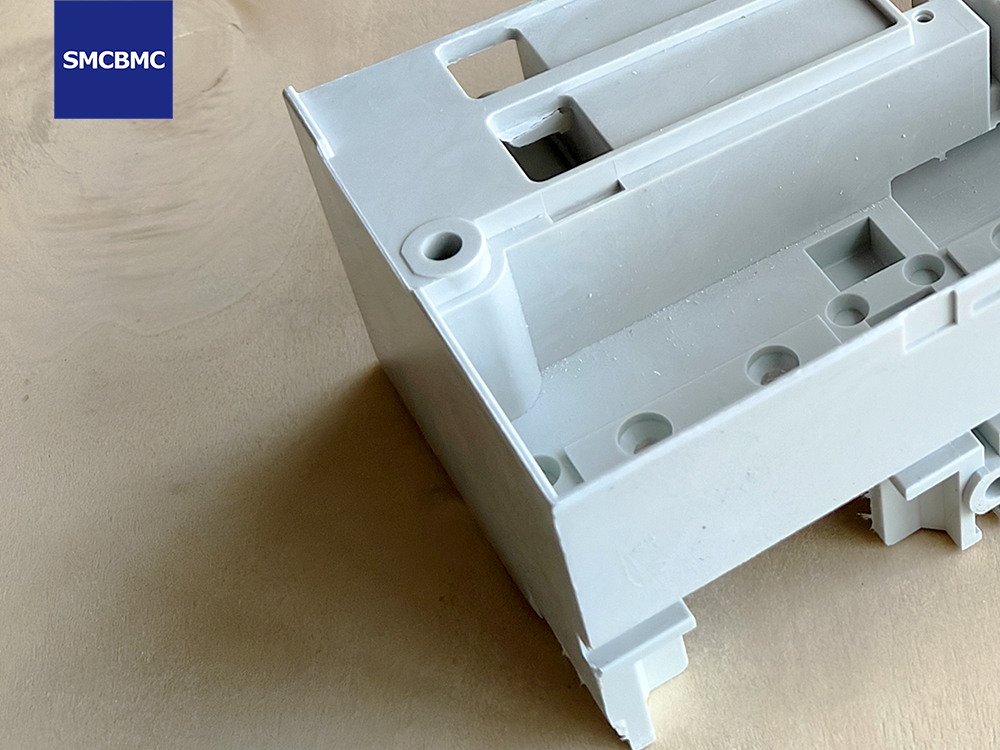

Used for coil fixation and insulation support, these components require high mechanical rigidity, low creep, and excellent electrical insulation to ensure structural stability under long-term electromagnetic vibrations and thermal cycling.

Used to insulate and separate busbars of different potential within switchgear, these components must excel in arc resistance, flame retardancy (typically UL94 V-0), and tracking resistance to prevent short-circuit accidents.

Electric motors are the heart of industrial power. Their internal insulation system defines their performance level and service life.

As the central connection point between motor windings and power sources, these components must withstand electrical, thermal, and mechanical stresses. Our materials offer stable electrical resistance, corona resistance, and excellent heat resistance (temperature index up to 155°C+).

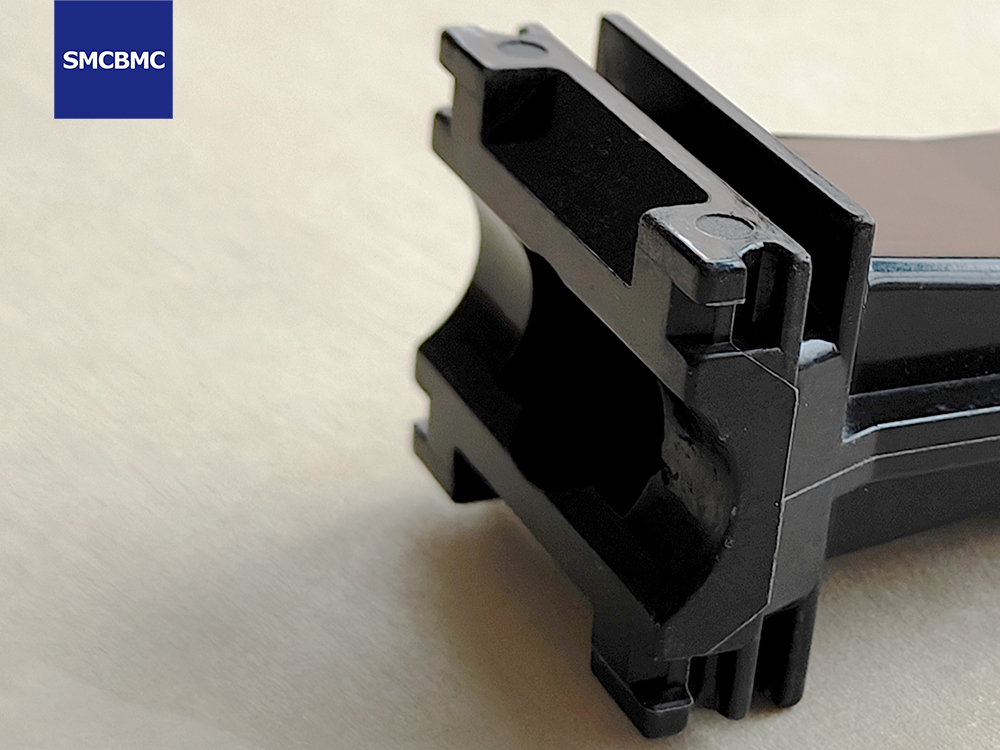

In explosive environments, any electrical spark can trigger disaster. Designed for explosion-proof motors, these insulation pillars and electrical insulation components feature high tracking resistance (CTI ≥ 600V) and completely isolate internal arcs from explosive gases, providing critical protection for chemical, mining, and other hazardous environments.

Insulation and protection at electrical connections form the first line of defense against faults.

As protective enclosures for power connections, these parts require excellent insulation, flame retardancy, sealing, corrosion resistance, and mechanical strength to protect internal connections from environmental damage.

Exceptional Electrical Insulation Performance

Our materials have high volume resistivity and dielectric strength, maintaining stable insulation performance under harsh conditions like high voltage and high frequency.

Intrinsic Safety & High Flame Retardancy

The materials themselves possess excellent flame retardant properties, achieving the UL94 V-0 highest rating without the need for halogenated flame retardants. They do not produce toxic molten drips, complying with stringent safety and environmental standards.

Outstanding Heat Resistance & Dimensional Stability

Stable performance in a wide temperature range from -50°C to 180°C, with high thermal deformation temperature and low thermal expansion coefficient, ensuring dimensional stability under prolonged high-temperature operation and structural stability under long-term stress.

Superior Mechanical Strength & Environmental Durability

High strength, high rigidity, corrosion resistance, UV resistance, and the ability to withstand harsh environments like outdoor conditions, humidity, salt mist, and chemical media, far exceeding regular engineering plastics in lifespan.

From transformer cushions securing large power equipment windings, to explosion-proof motor pillars ensuring absolute safety; from terminal boards carrying electrical connections to terminal box housings protecting every electrical node—we are dedicated to using the most reliable materials science to create an invisible safety shield for the energy, industrial manufacturing, rail transit, and new energy sectors.

We look forward to deepening collaboration with electrical equipment manufacturers, motor manufacturers, and system engineers to jointly design and develop next-generation, more efficient, compact, and reliable electrical insulation solutions.

Wenzhou Jintong Complete Appliances Co., Ltd. (Jintong) is a high-tech enterprise specializing in the R&D, production, and precision molding of high-performance BMC/SMC thermosetting composites.

We focus on providing key insulation, structural, and protective components for industries including electrical power, industrial motors, new energy vehicles, and specialized equipment.