Date | 2026-01-28 08:23:57

In the construction of modern transportation corridors and energy networks, reliability, durability, and safety are non-negotiable requirements. Leveraging deep expertise in high-performance thermosetting composites such as BMC (Bulk Molding Compound) and SMC (Sheet Molding Compound), Wenzhou Jintong delivers proven component solutions for rail transit, power distribution, automotive, and communication infrastructure.

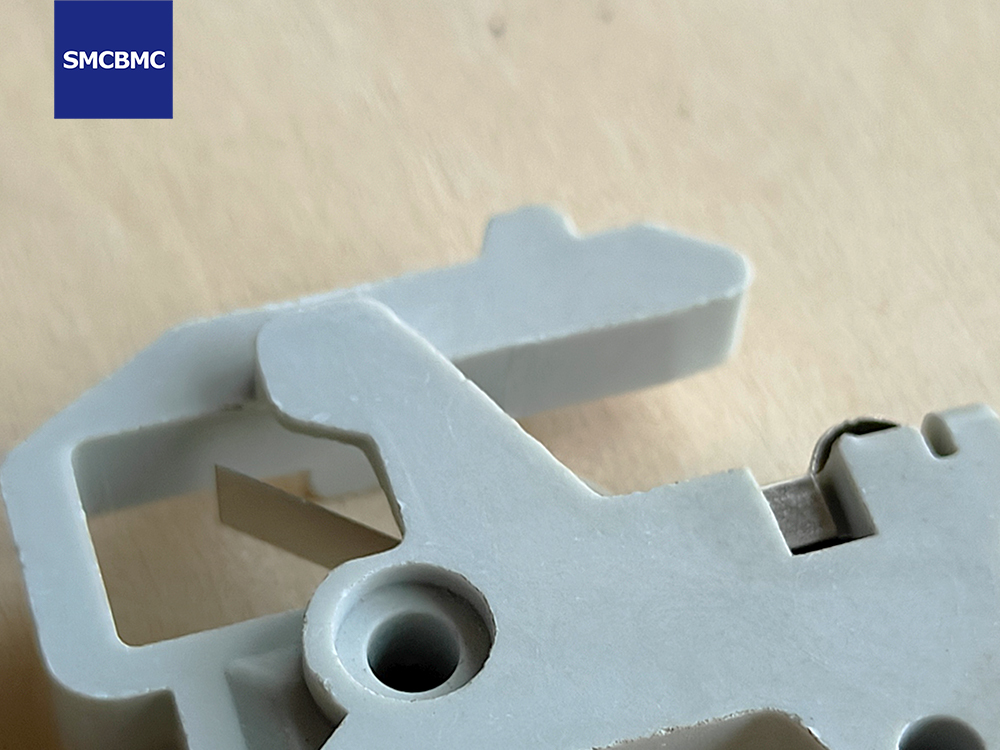

From automotive motor terminal blocks ensuring secure electrical connections, to railway return rail brackets and turnout components supporting safe train operation, and to signal enclosures and water & electricity meter boxes protecting critical equipment, our composite solutions are engineered to perform under harsh environmental and mechanical conditions—ensuring long-term infrastructure stability.

Rail transportation places exceptionally high demands on mechanical strength, flame retardancy, fatigue resistance, and environmental durability. Our BMC/SMC composite solutions are deeply integrated into rail systems:

Return rail brackets and turnout components are safety-critical structural parts. Our composite materials provide:

High mechanical strength and stiffness

Excellent dimensional stability

Outstanding weather resistance

These properties ensure consistent performance under long-term vibration, impact loads, and extreme climate variations.

Our composites are widely used in:

Interior and exterior rail vehicle panels

Electrical compartment covers

Trackside cable supports and cable trays

Signal enclosures and power distribution cabinets

These components are lightweight, corrosion-resistant, flame-retardant (compliant with EN 45545), and exhibit low smoke and low toxicity, significantly improving system safety and maintenance efficiency.

From backbone power networks to end-user metering, composite materials offer a superior alternative to traditional metals.

Cable supports and cable trays made from BMC/SMC provide:

Electrical insulation

Excellent corrosion resistance

Lightweight structure for easier installation

Compared with metal systems, they deliver longer service life with minimal maintenance.

Power enclosures, including outdoor ring main unit housings, achieve high ingress protection and weather resistance, safeguarding sensitive internal equipment.

Automotive motor terminal blocks require:

High electrical insulation

Thermal aging resistance

Strong pull-out strength

Our composite solutions meet these demands reliably.

For water and electricity meter boxes, which are essential public infrastructure components, BMC/SMC materials combine durability, insulation, anti-theft properties, and aesthetic stability, making them the preferred upgrade choice.

In applications demanding both structural precision and environmental endurance, composite materials demonstrate unique value.

Composite materials used in antenna reflectors and support structures offer:

High geometric accuracy

Lightweight yet high stiffness

Excellent resistance to temperature extremes and wind loads

These advantages ensure stable signal transmission under challenging outdoor conditions.

Our material platforms can be flexibly adapted to additional power enclosure and special structural applications, supporting evolving infrastructure needs.

Inherent flame retardancy (up to UL 94 V-0), high electrical insulation resistance, and excellent arc resistance elevate system safety at the material level.

The combination of high strength and low density enables significant weight reduction while delivering outstanding impact and fatigue resistance—far exceeding conventional materials.

Superior resistance to corrosion, UV exposure, salt spray, chemicals, and a wide operating temperature range (-60 °C to 180 °C) ensures long service life with low or zero maintenance.

Complex structures can be molded in a single process, integrating multiple functions, reducing assembly steps, improving consistency, and lowering total system cost.

Environmentally responsible manufacturing processes and long product life cycles contribute to low carbon footprints, supporting green and sustainable infrastructure development.

From rail vehicles in motion, to utility meter boxes across cities and rural areas; from satellite antennas carrying data, to cable supports and power enclosures securing energy transmission—we participate in shaping modern infrastructure through advanced composite materials.

We welcome collaboration with rail equipment manufacturers, power system suppliers, automotive OEMs, and communication integrators to jointly develop future-ready, high-performance component solutions.

Wenzhou Jintong Complete Electrical Co., Ltd. (Wenzhou Jintong) is a high-tech enterprise specializing in BMC/SMC thermosetting composite material development, precision mold design, and component molding.

We provide customized, high-reliability component solutions for rail transit, power & electrical systems, automotive, and communication industries.