Date | 2026-02-01 08:24:15

In many engineering discussions, replacing metal with BMC is often described as a simple material switch.

In reality, BMC molding represents a complete manufacturing strategy upgrade, involving structural redesign, process control, and long-term reliability optimization—not merely a change from metal to plastic.

At Wenzhou Jintong Complete Electric Co., Ltd., we work with customers to treat BMC molding as a system-level metal replacement strategy, enabling weight reduction, cost stability, safety enhancement, and design integration across electrical, motor, rail, and energy applications.

Rising metal prices, supply volatility, corrosion issues, and increasing safety standards are forcing manufacturers to rethink traditional metal-based designs.

Metal components often bring:

High weight and inertia

Corrosion and surface treatment costs

Electrical conductivity risks

Multi-part assemblies and complex machining

Cost exposure to raw material price fluctuations

BMC (Bulk Molding Compound) addresses these challenges at the system level—not by imitation, but by redesign.

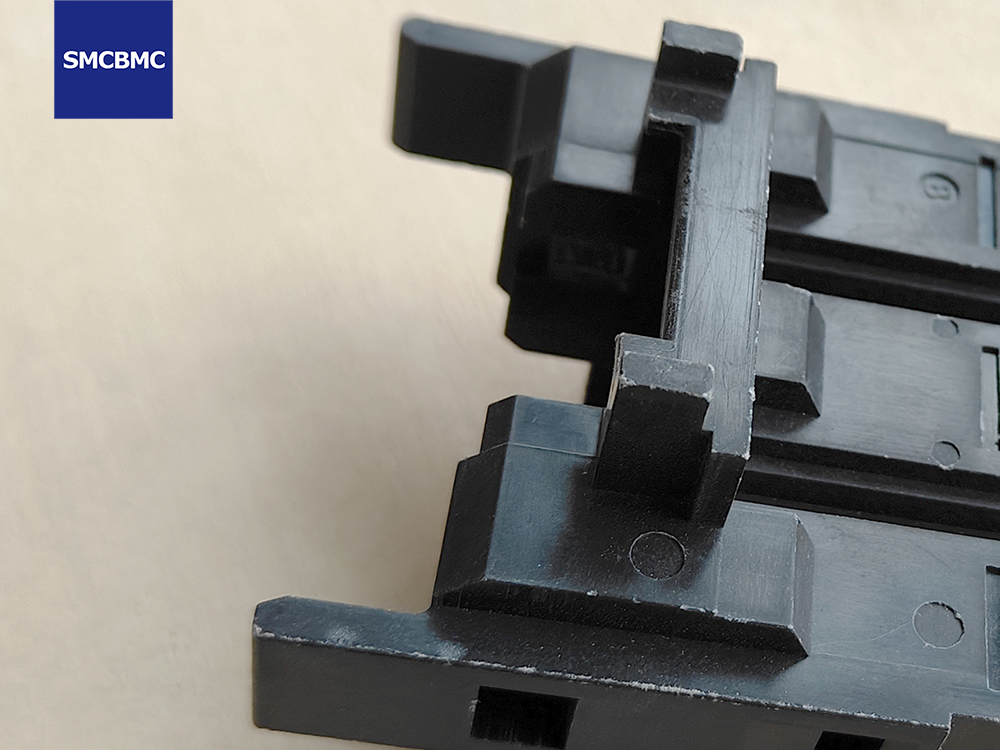

Unlike metal stamping or machining, BMC molding allows:

Rib-reinforced structures

Integrated insulation and mechanical support

Embedded metal inserts molded in one step

Elimination of fasteners, welding, and secondary insulation parts

This turns multiple metal components into a single functional composite part, improving consistency and reliability.

BMC is inherently:

Electrically insulating

Arc-resistant

Flame-retardant (UL94 V-0 achievable, even at thin walls)

High CTI (≥600V possible)

For applications such as:

MCB housings

Motor terminal boards

Busbar supports

Transformer insulation blocks

BMC does not require insulation—it is the insulation.

Typical benefits include:

30–60% weight reduction compared to steel or aluminum

High flexural strength (120–200 MPa achievable)

Excellent vibration damping performance

Stable mechanical properties across wide temperature ranges

This is especially critical for:

Electric motors

Rail transit components

Energy infrastructure exposed to vibration and fatigue

Unlike metals tied to global commodity markets, BMC molding offers:

Stable formulation-based cost structure

High repeatability through controlled mold temperature and pressure curves

Low scrap rate in mature processes

Predictable long-term supply

For procurement teams, this means risk reduction, not just cost savings.

Replacing metal with BMC is not plug-and-play.

Successful projects require:

Material formulation matched to load, temperature, and electrical stress

Mold design based on BMC flow behavior and shrinkage control

Precise molding process windows (temperature, pressure, cure time)

At Wenzhou Jintong, we integrate:

BMC material development

Precision mold design

Mass-production molding control

into a single closed-loop system—ensuring that the performance designed on paper is achieved in real production.

Motor terminal boards and end caps

Electrical insulation supports and spacers

Rail transit structural and insulation components

Power distribution housings and enclosures

Energy equipment structural-insulating parts

In these applications, BMC does not replace metal piece by piece—

it replaces the logic of metal-based design.

BMC molding is most powerful when viewed as:

A design strategy

A process-controlled manufacturing system

A long-term reliability solution

Not just as an alternative material.

Wenzhou Jintong Complete Electric Co., Ltd. specializes in:

High-performance BMC/SMC thermosetting composite materials

Precision mold design and manufacturing

Mass-production compression molding for critical structural and insulation components

We support customers in electrical, motor, rail transit,new energy, and industrial equipment industries with integrated material–mold–process solutions.