Date | 2026-01-30 10:24:16

In BMC (Bulk Molding Compound) compression molding, material formulation alone does not determine final part quality. Even the best-performing BMC compound can fail to deliver its designed properties if mold temperature distribution and pressure curves are not precisely controlled.

For high-reliability applications—such as electrical insulation components, motor parts, MCB housings, and structural elements—mold temperature and pressure curves define whether material potential becomes real performance.

At Wenzhou Jintong Complete Electric Co., Ltd.(Wenzhou Jintong) , we treat mold temperature and pressure not as machine settings, but as core engineering parameters directly linked to part safety, consistency, and lifecycle reliability.

Mold temperature is the primary driver of BMC curing behavior. Unlike thermoplastics, BMC undergoes an irreversible crosslinking reaction, making temperature control especially critical.

Material Flow Behavior

Insufficient temperature increases viscosity, leading to incomplete filling, weld lines, and fiber misalignment.

Excessive temperature may cause premature skin curing, restricting flow and trapping gas.

Cure Kinetics & Degree of Crosslinking

Uniform mold temperature ensures full curing throughout the part thickness, preventing soft cores or brittle surfaces.

Internal Stress & Dimensional Stability

Uneven thermal gradients result in residual stress, warpage, and long-term creep—especially critical for electrical insulation parts.

In practice, temperature uniformity (±5°C across the mold cavity) matters more than absolute temperature values.

Pressure in BMC molding is not static—it is a time-dependent curve that must align with material flow and curing stages.

Complete Fiber Wet-Out

Gradual pressure buildup ensures short glass fibers are uniformly distributed without breakage.

Void and Porosity Elimination

Optimized pressure timing allows trapped air and volatiles to escape before full gelation.

High Mechanical Integrity

Correct peak pressure ensures part density consistency, directly affecting bending strength, impact resistance, and fatigue life.

A poorly designed pressure curve often leads to:

Internal voids

Burn marks

Surface cracks

Reduced electrical insulation performance

Mold temperature and pressure must be engineered as a coupled system, not adjusted independently.

Higher mold temperatures require earlier pressure application to control flow.

Lower temperatures demand longer pressure holding to ensure complete curing.

Thick-wall parts and thin-wall flame-retardant components require different curve profiles.

This interaction defines:

Final fiber orientation

Shrinkage behavior

Flame retardancy performance at thin sections (e.g. V-0 at 0.4 mm)

Long-term dimensional stability

Many failures attributed to “material problems” are actually process mismatches.

At Wenzhou Jintong, we operate under a fully integrated BMC engineering model:

Material Formulation

BMC recipes are developed with known flow windows, cure profiles, and pressure sensitivity.

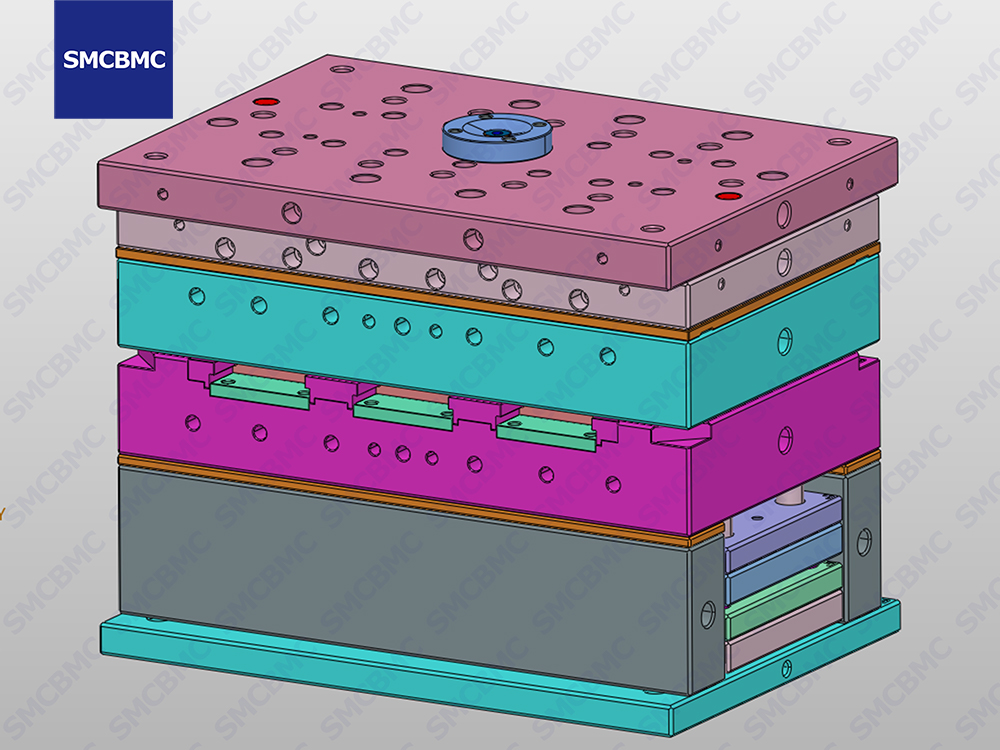

Mold Engineering

Runner design, venting layout, and thermal zones are matched to material rheology.

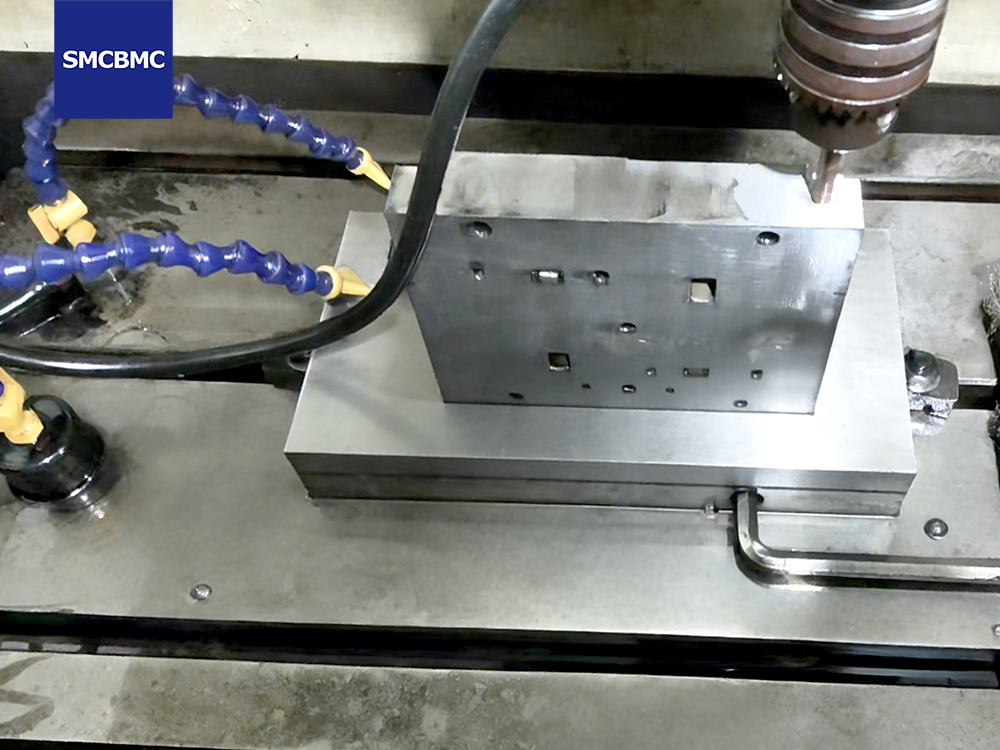

Process Validation

Mold temperature mapping and pressure curve validation are performed before mass production.

This closed-loop control ensures that laboratory material performance is consistently transferred into mass-produced parts.

With optimized mold temperature and pressure curves, BMC components achieve:

Stable electrical insulation resistance over time

Reliable flame retardancy (UL94 V-0, even at thin wall sections)

High bending strength and vibration resistance

Low scrap rates and high batch-to-batch consistency

Predictable performance in harsh thermal and electrical environments

In BMC molding, performance is engineered, not assumed.

Mold temperature and pressure curves are not production parameters to be adjusted on the shop floor—they are design-level decisions that define part reliability, safety margins, and lifecycle cost.

Choosing a BMC supplier who understands and controls this interaction is often the difference between a part that merely passes initial tests—and one that performs reliably for decades.

Wenzhou Jintong Complete Electric Co., Ltd. specializes in high-performance BMC/SMC thermosetting composite materials, precision mold development, and compression molding of critical electrical and structural components.

We provide integrated solutions for:

Electrical insulation components

Motor and power system parts

Flame-retardant housings and structural composites

From material formulation to mold design and process control, we help customers convert material potential into engineering certainty.