Date | 2026-02-04 09:51:25

In modern electrical and industrial systems, flame retardancy is often treated as a primary material selection criterion. Safety certifications, regulatory requirements, and fire prevention standards all emphasize resistance to ignition and flame propagation.

However, real-world field failures often reveal a different story.

In many cases, components do not fail because they ignite — they fail because they deform, loosen, or lose dimensional precision long before fire becomes a risk. This raises an important engineering question:

In actual operating environments, which performance parameter becomes the first point of failure — flame retardancy or dimensional stability?

Understanding this relationship is essential when designing high-reliability components for power distribution, motors, rail transit, and new energy systems.

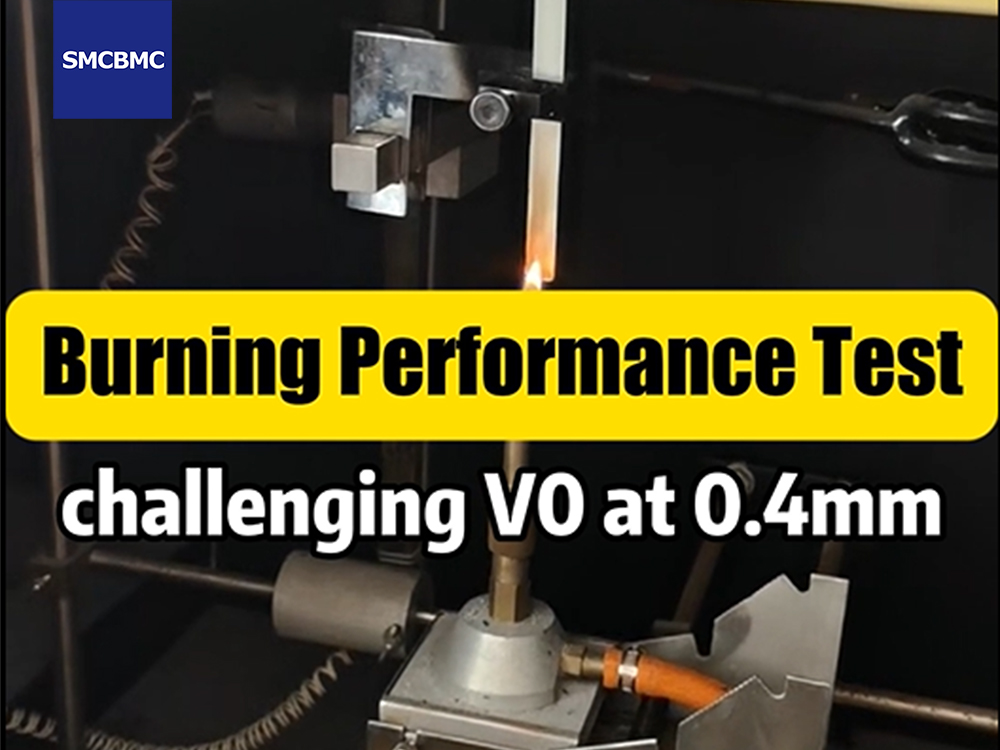

Flame retardancy is critical for electrical safety compliance. Materials used in switchgear, circuit breakers, battery systems, and insulation structures must meet strict regulatory requirements such as UL94 V-0 or equivalent fire performance standards.

Flame retardant materials provide:

Resistance to ignition

Self-extinguishing behavior

Reduced flame propagation

Protection during short-circuit or overload events

For many industries, achieving flame retardancy is considered a baseline requirement rather than a differentiating feature.

However, flame retardancy primarily addresses extreme failure scenarios, not everyday operational stresses.

Electrical and mechanical systems operate continuously under combined environmental and mechanical loads, including:

Thermal cycling

Mechanical preload and vibration

Humidity exposure

Long-term electrical stress

Outdoor weathering and UV exposure

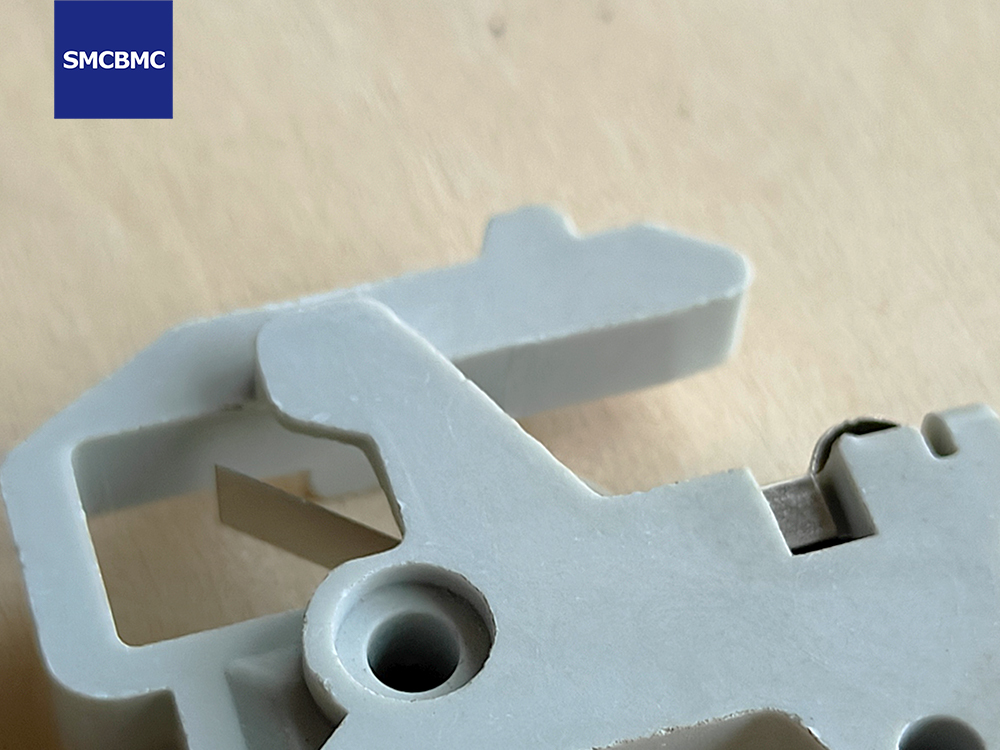

Under these conditions, components may gradually experience:

Loss of mechanical clamping force

Increased contact resistance

Reduced creepage and clearance distances

Seal failure in enclosures

Progressive misalignment of conductive structures

These failures rarely trigger immediate fire hazards but significantly reduce system reliability and lifespan. Over time, dimensional drift can indirectly increase electrical risk, making it a root cause of long-term performance degradation.

Dimensional stability refers to a material’s ability to maintain its original geometry throughout temperature changes, mechanical loading, and environmental exposure.

In high-voltage and precision electrical assemblies, dimensional integrity directly influences:

Electrical insulation performance

Contact reliability

Structural load distribution

Assembly tolerance control

Long-term sealing effectiveness

Even slight deformation can compromise system safety margins, particularly in compact designs where creepage distances and mechanical tolerances are tightly controlled.

Bulk Molding Compound (BMC) offers a unique combination of flame retardancy and dimensional reliability because of its thermosetting composite structure.

Unlike thermoplastics, BMC forms a permanently crosslinked structure during curing. This prevents material softening or flow when exposed to elevated temperatures, maintaining dimensional accuracy over time.

Glass fiber reinforcement and mineral fillers provide:

Reduced thermal expansion

Improved creep resistance under sustained load

Enhanced structural rigidity

Consistent shrinkage behavior during molding

BMC demonstrates extremely low water absorption compared to hygroscopic engineering plastics, preventing swelling and dimensional distortion in humid environments.

Modern BMC formulations can achieve high flame retardancy levels, including UL94 V-0 classification, without significantly compromising mechanical or dimensional performance.

Many flame-retardant thermoplastics meet fire safety standards but remain vulnerable to:

Thermal deformation

Long-term creep

Stress relaxation under mechanical loading

Moisture-induced dimensional changes

In such cases, components may pass safety certification but fail during long-term service due to loss of structural integrity.

BMC helps bridge this gap by providing simultaneous control over fire performance and dimensional reliability.

Dimensional stability cannot be achieved through material formulation alone. It requires precise coordination between:

Material composition

Mold design

Processing parameters

At Wenzhou Jintong, dimensional reliability is engineered through:

Application-specific BMC material development

Mold designs optimized for fiber orientation and shrinkage balance

Uniform mold temperature control

Optimized compression pressure and curing cycles

Batch-level process consistency monitoring

This integrated manufacturing approach ensures that laboratory performance translates into repeatable industrial production quality.

For engineers and OEM manufacturers, the most critical question is no longer:

“Is the material flame retardant?”

But rather:

“Will the material maintain structural and electrical integrity throughout its service life?”

In many applications, flame resistance protects against catastrophic events, while dimensional stability determines everyday operational reliability.

True system safety requires both.

As electrical systems become more compact, energy-dense, and performance-sensitive, material selection must consider long-term structural consistency alongside traditional safety metrics.

BMC is not simply a flame-retardant composite — it is a reliability-focused engineering material designed to maintain dimensional integrity across demanding operational environments.

Wenzhou Jintong Complete Electrical Co., Ltd. specializes in high-performance BMC/SMC thermosetting composites, precision mold design, and compression molding of critical electrical and structural components.

We provide integrated solutions for electrical insulation systems, motors, rail transit equipment, new energy infrastructure, and industrial applications, delivering materials and components engineered for safety, stability, and long-term reliability.