Date | 2026-01-12 07:55:48

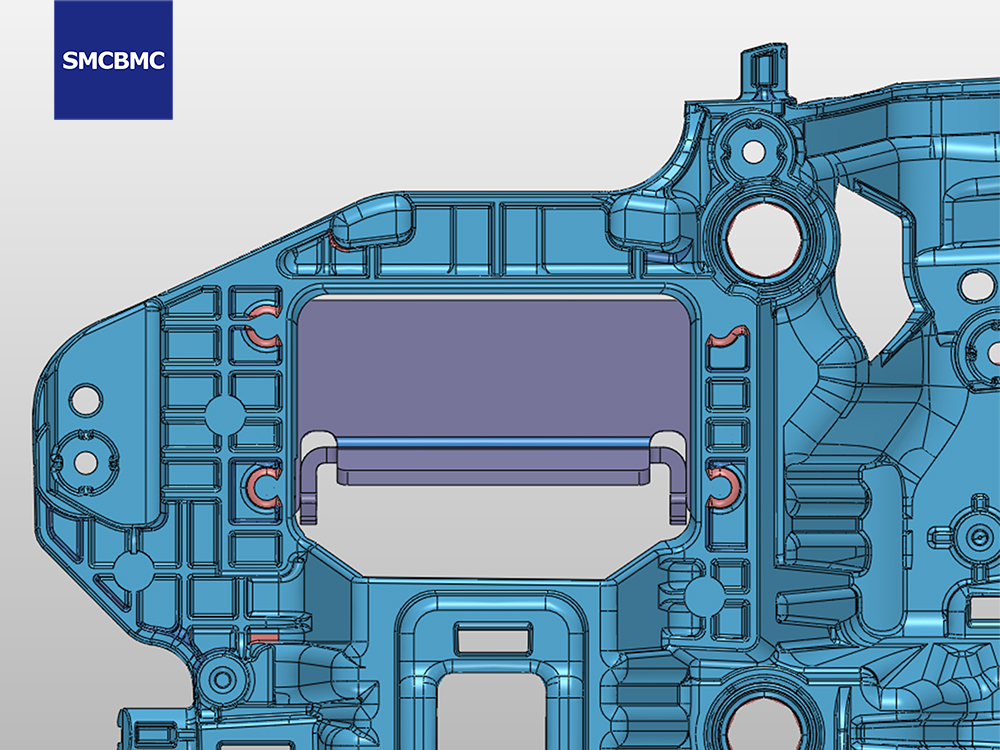

In BMC/SMC thermoset molding, venting and temperature control are two of the most critical—yet often underestimated—factors in mold design.

Improper venting can cause gas traps, burns, and surface defects, while unstable temperature control may lead to incomplete curing, warpage, or inconsistent mechanical performance.

For high-reliability applications such as electrical, rail, automotive, and industrial components, these two systems directly determine molding stability and product consistency.

Unlike thermoplastics, BMC and SMC materials release gases during the curing reaction.

If gases cannot escape efficiently, defects such as short shots, burn marks, porosity, or surface blistering may occur.

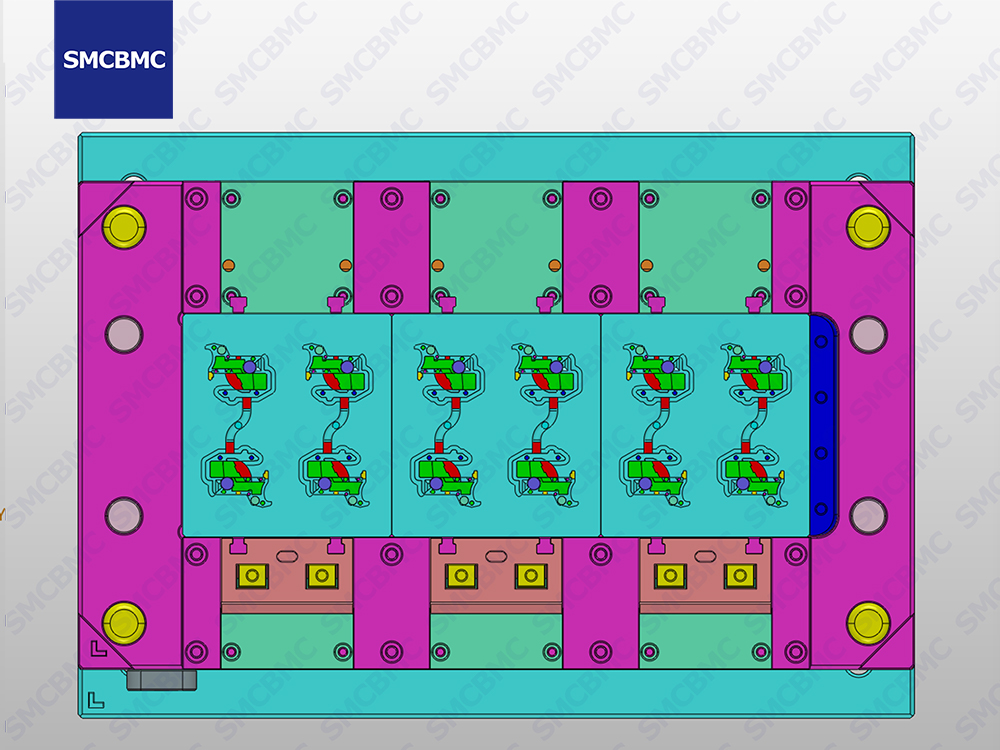

Vent depth: typically 0.01–0.03 mm, depending on fiber length and resin viscosity

Vent width: wide enough to release gas efficiently without causing flash

Vent location: placed at the end of flow paths and potential air-trap areas

Progressive venting: multi-stage venting is recommended for large or complex parts

Well-designed venting ensures:

Complete cavity filling

Reduced internal stress

Improved surface finish

Lower reject rates in mass production

Thermoset materials are highly sensitive to temperature.

Uneven mold temperature may result in partial curing, internal cracks, or dimensional instability.

Typical mold surface temperature: 140–170°C (depending on formulation)

Temperature deviation across cavity surface: ≤ ±5°C

Independent heating zones for complex or thick-walled parts

Optimized heater placement for uniform heat distribution

Avoidance of local overheating near gates or thick sections

Stable temperature feedback control to ensure process repeatability

Effective temperature control leads to:

Consistent curing degree

Stable mechanical and electrical properties

Reduced cycle time

Improved mold life

In BMC/SMC tooling, venting and temperature control must be designed together.

Higher mold temperatures accelerate curing—but also increase gas release speed.

Without proper venting, this combination may intensify defects rather than eliminate them.

A balanced design approach ensures:

Controlled material flow

Predictable curing behavior

High process stability in long production runs

With over 20 years of experience in thermoset materials and tooling, Wenzhou Jintong designs molds from a material-driven perspective.

Our advantages include:

Deep understanding of BMC/SMC curing behavior

Proven venting strategies for complex electrical components

Precision temperature control design based on real production data

Close integration between mold design and molding process optimization

We believe that stable venting and precise temperature control are the foundation of high-quality thermoset products—not optional features.