Date | 2026-01-15 07:39:51

In modern motor design—especially for EV drive motors, industrial motors, HVAC motors, and sealed electric motors—vibration and noise control has become a critical performance indicator, directly affecting efficiency, reliability, and service life.

Compared with traditional metal housings and supports, Bulk Molding Compound (BMC) offers inherent vibration damping advantages that are increasingly valued by advanced motor manufacturers.

Motor vibration is not only a noise issue. Excessive vibration can lead to:

Bearing fatigue and premature failure

Reduced insulation life of windings

Loosening of fasteners and assemblies

Decreased overall system efficiency

As motors move toward higher speed, higher power density, and lighter weight, controlling vibration at the material and structural level becomes essential.

BMC is a fiber-reinforced thermosetting composite, consisting of polyester resin, chopped glass fibers, and functional fillers. Unlike metals, which transmit vibration efficiently, BMC exhibits intrinsic damping behavior due to its viscoelastic resin matrix.

Key material characteristics include:

High internal damping coefficient, absorbing vibration energy rather than transmitting it

Reduced resonance amplification compared with steel or aluminum structures

Stable damping performance over a wide temperature range

This makes BMC particularly effective in suppressing mid- and high-frequency vibrations commonly generated by electric motors.

Beyond material properties, BMC enables highly integrated structural design, further improving vibration performance:

Complex rib structures can be molded directly to increase stiffness without excessive weight

Motor housings, end covers, and supports can be integrated into fewer parts, reducing joint-induced vibration

Uniform wall thickness minimizes stress concentration and vibration hotspots

This design freedom allows engineers to tune stiffness and damping simultaneously, something difficult to achieve with metal housings.

| Aspect | Metal (Steel / Aluminum) | BMC Composite |

|---|---|---|

| Vibration transmission | High | Low |

| Damping capability | Poor | Excellent |

| Noise radiation | Higher | Lower |

| Weight | Heavy | Lightweight |

| Corrosion resistance | Limited | Excellent |

As a result, BMC motor components often demonstrate lower noise levels and smoother operation under the same working conditions.

BMC vibration damping advantages are widely utilized in:

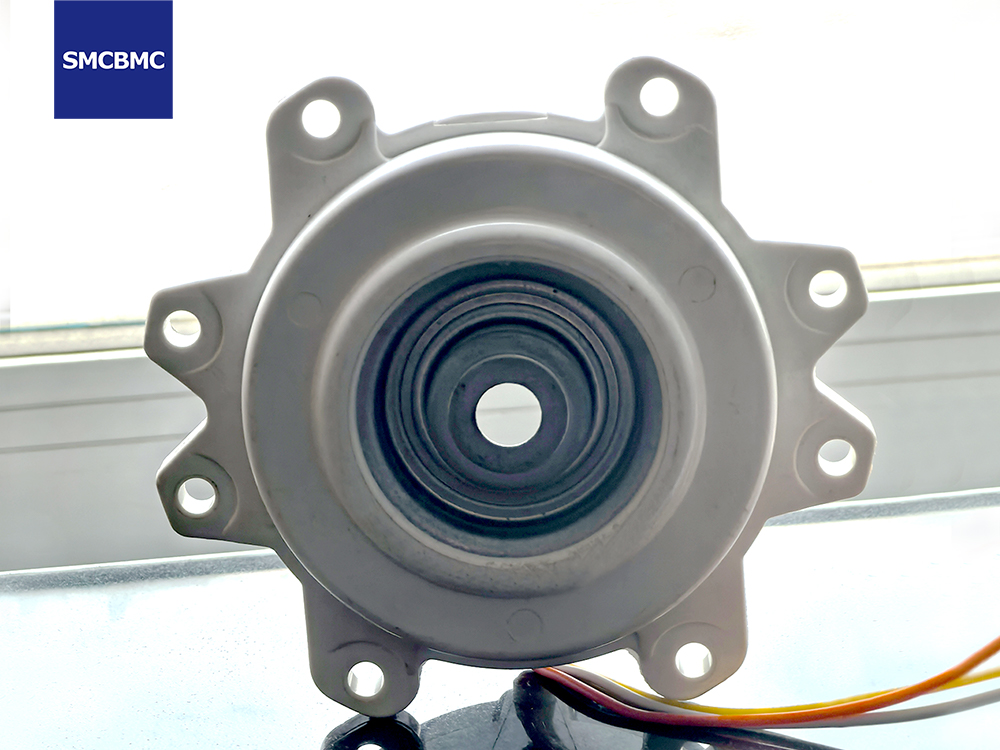

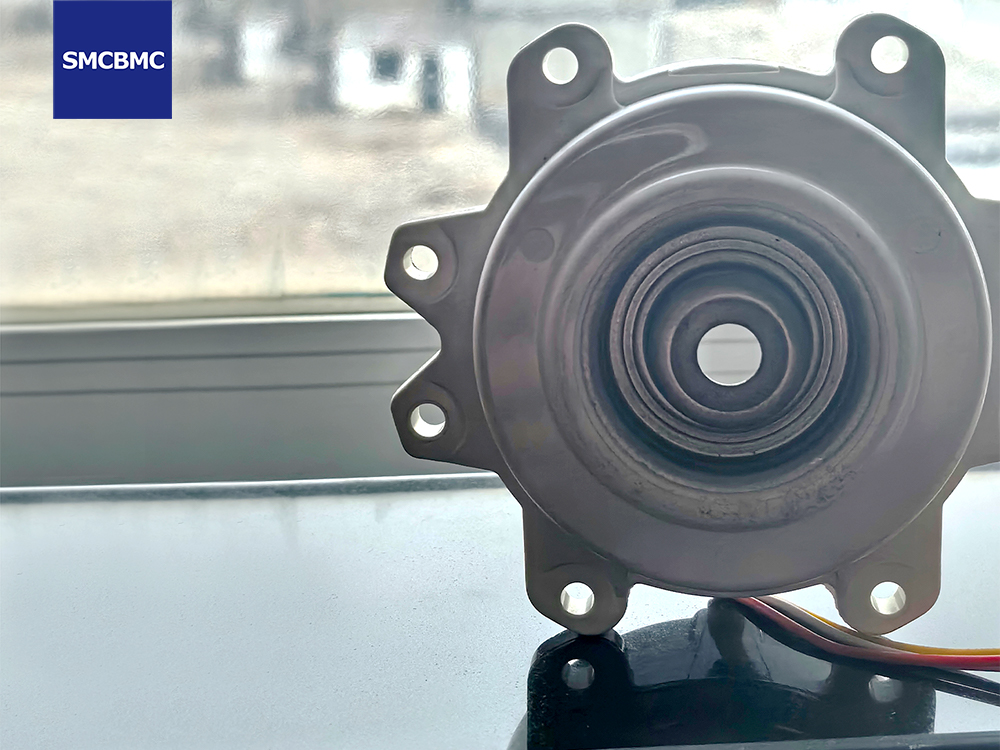

Encapsulated motors (BMC motors)

EV auxiliary and drive motor housings

Industrial motor end shields and brackets

Pump motors and HVAC fan motors

In many cases, BMC enables metal replacement while simultaneously improving NVH (Noise, Vibration, Harshness) performance.

Unlike elastomer-based damping solutions, BMC provides long-term stable damping performance without creep, softening, or aging-related degradation. Its dimensional stability ensures that vibration behavior remains consistent throughout the motor’s service life.

In motor applications where quiet operation, durability, and reliability are critical, BMC is more than a lightweight alternative—it is a functional material choice.

By combining intrinsic vibration damping, structural design freedom, and excellent thermal and electrical properties, BMC enables motor manufacturers to achieve higher performance with greater design certainty.

About Jintong

Wenzhou Jintong provides integrated BMC material formulation, precision tooling, and compression molding solutions for motor components and electrical insulation parts. We help customers translate material advantages into stable, high-volume manufacturing success.