Date | 2026-01-16 13:50:05

For decades, metal has been synonymous with strength and reliability in industrial manufacturing. Steel frames, aluminum housings, and copper components have long been considered the “safe choice” for electrical, automotive, and energy applications.

However, as industries pursue lightweight design, cost efficiency, corrosion resistance, and functional integration, a fundamental question continues to surface:

Does replacing metal with plastics or composites actually compromise reliability?

The short answer is: not when advanced materials like BMC, SMC, and epoxy composites are properly engineered and applied.

In many cases, reliability is not reduced—it is significantly enhanced.

A common misconception is to equate material hardness or weight with reliability. In reality, reliability is defined by long-term system performance under real operating conditions, including:

Electrical stress

Mechanical load and vibration

Thermal cycling

Humidity, UV exposure, and chemical corrosion

Fire and safety compliance

Traditional metals perform well in some of these dimensions—but poorly in others.

For example:

Metals conduct electricity (a disadvantage in insulation systems)

Metals corrode in humid or polluted environments

Metals fatigue under vibration and cyclic stress

Metal assemblies often require multiple parts, fasteners, and joints—each a potential failure point

Reliability, therefore, is not about strength alone, but about balanced performance across multiple stress factors.

Bulk Molding Compound (BMC) and Sheet Molding Compound (SMC) are not conventional plastics.

They are engineered thermoset composites, consisting of:

Resin systems (polyester, vinyl ester, epoxy-modified)

Glass fiber reinforcement

Functional fillers (flame retardant, arc resistance, thermal stability)

Precisely controlled molding processes

This allows designers to engineer reliability into the material itself, rather than compensating for material weaknesses later.

In electrical and energy systems, reliability starts with insulation.

BMC and SMC provide:

High dielectric strength

Stable insulation resistance

Excellent tracking resistance (CTI)

Superior arc resistance

Unlike metal housings that require additional insulation layers, composite materials integrate insulation into the structure itself, reducing system complexity and failure risk.

Metal corrosion is one of the leading causes of long-term reliability loss.

Composite materials:

Do not rust or oxidize

Resist moisture, salt fog, chemicals, and industrial pollution

Maintain mechanical and electrical properties over decades

This makes BMC/SMC ideal for:

Outdoor electrical enclosures

Photovoltaic junction boxes

Railway and urban power distribution systems

In motors, rail transit, and rotating equipment, vibration—not static load—is often the real reliability killer.

Compared to metal:

Composites naturally damp vibration

Reduce noise and resonance

Improve fatigue life of connected components

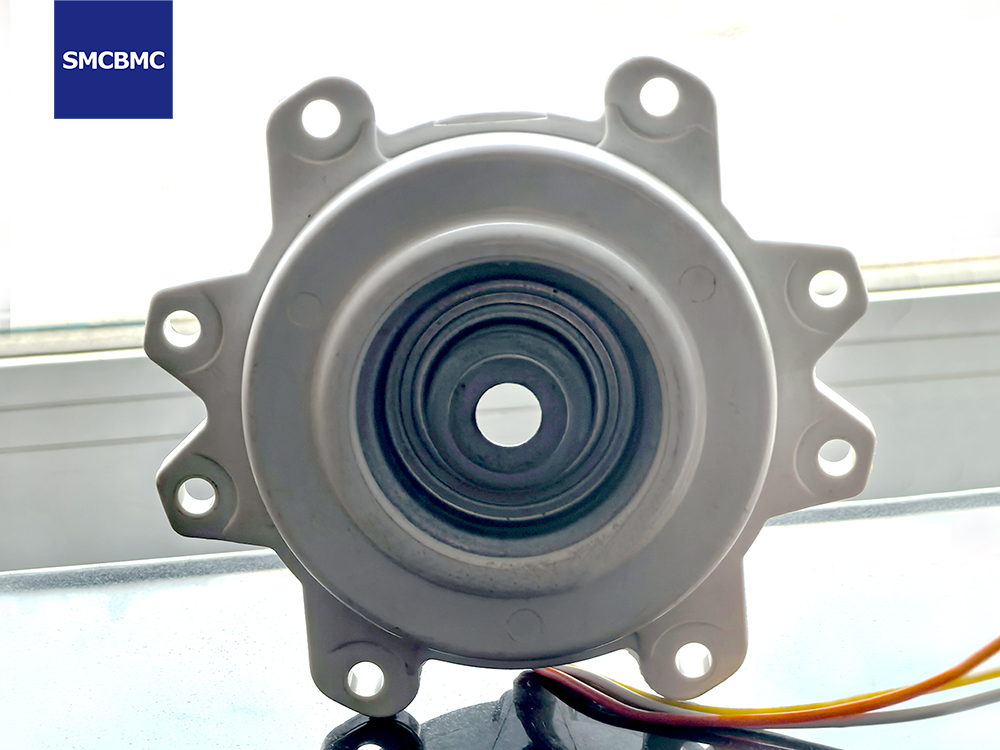

This is why BMC is increasingly used in:

Motor housings

End caps and structural supports

Rail transit electrical components

Advanced BMC formulations can achieve:

Glass transition temperatures (Tg) above 200–230°C

Low thermal expansion

Stable dimensions under thermal cycling

Unlike thermoplastics, thermoset composites do not soften or creep at elevated temperatures, ensuring consistent long-term performance.

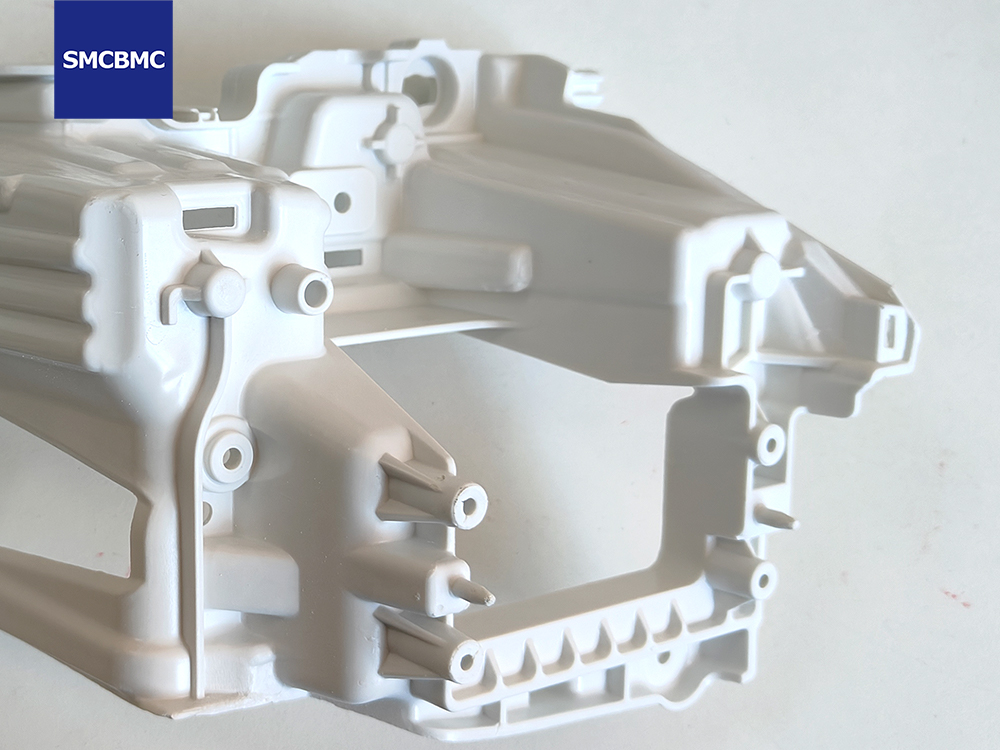

One of the most overlooked advantages of replacing metal with composites is functional integration.

BMC/SMC molding allows:

Complex geometries in a single part

Integration of ribs, insulation barriers, mounting points

Reduced fasteners and assembly steps

Fewer parts mean:

Fewer interfaces

Fewer tolerances stacking

Fewer failure modes

From a reliability engineering standpoint, integration is often more important than raw material strength.

Failures typically occur when:

Commodity plastics are used instead of engineering composites

Material selection ignores real operating conditions

Molds and processes are not optimized for the compound

Electrical, thermal, and mechanical stresses are evaluated independently instead of system-wide

In other words, poor engineering decisions—not composite materials—cause reliability issues.

As industries move toward:

Electrification

Smart grids

Renewable energy

Lightweight transportation

Reliability will depend less on “overbuilt metal parts” and more on:

Material-property matching

Predictable long-term behavior

Integrated design and manufacturing

Advanced composites like BMC, SMC, and epoxy-based systems are not compromises—they are solutions engineered for modern reliability requirements.

“Plastic replacing metal” is not about cost cutting or material downgrading.

It represents a shift from material-centric thinking to performance-centric engineering.

When designed correctly, advanced composite materials deliver higher electrical safety, better environmental resistance, improved vibration behavior, and more stable long-term performance than traditional metals.

Reliability is not what a material looks like.

Reliability is what it continues to deliver—year after year, under real-world conditions.