Date | 2026-01-29 07:41:58

In BMC (Bulk Molding Compound) molding, product quality is never determined by a single factor.

Material formulation, mold design, and molding process parameters form an inseparable system.

When these three elements are developed and controlled independently, defects, instability, and hidden risks are almost inevitable.

This is why integrated material–mold–process control has become a critical success factor in high-reliability BMC applications, especially in electrical insulation, motors, rail transit, and energy equipment.

In traditional supply models, responsibilities are divided:

Material suppliers focus on resin systems and fiber content

Mold makers focus on cavity geometry and tooling accuracy

Molding plants focus on press parameters and output efficiency

However, BMC is not a “forgiving” material. Its viscosity evolution, fiber distribution, curing kinetics, and gas release behavior are highly sensitive to small mismatches between these stages.

Common issues caused by fragmentation include:

Flow imbalance and fiber segregation

Surface burn marks or internal porosity

Dimensional deviation after curing

Inconsistent electrical and mechanical performance across batches

When problems arise, accountability becomes unclear—and the cost is paid in time, scrap, and reliability risk.

Integrated BMC molding starts with application-driven material design, not generic grades.

Key material variables must be aligned with the final part function:

Resin system selection (heat resistance, arc resistance, CTI level)

Fiber length and loading (mechanical strength vs. flowability)

Filler system (shrinkage control, surface quality, thermal stability)

Flame-retardant strategy (halogen-free, UL94 V-0, thin-wall performance)

Without understanding mold geometry and process windows, even high-performance BMC formulations cannot deliver consistent results in real production.

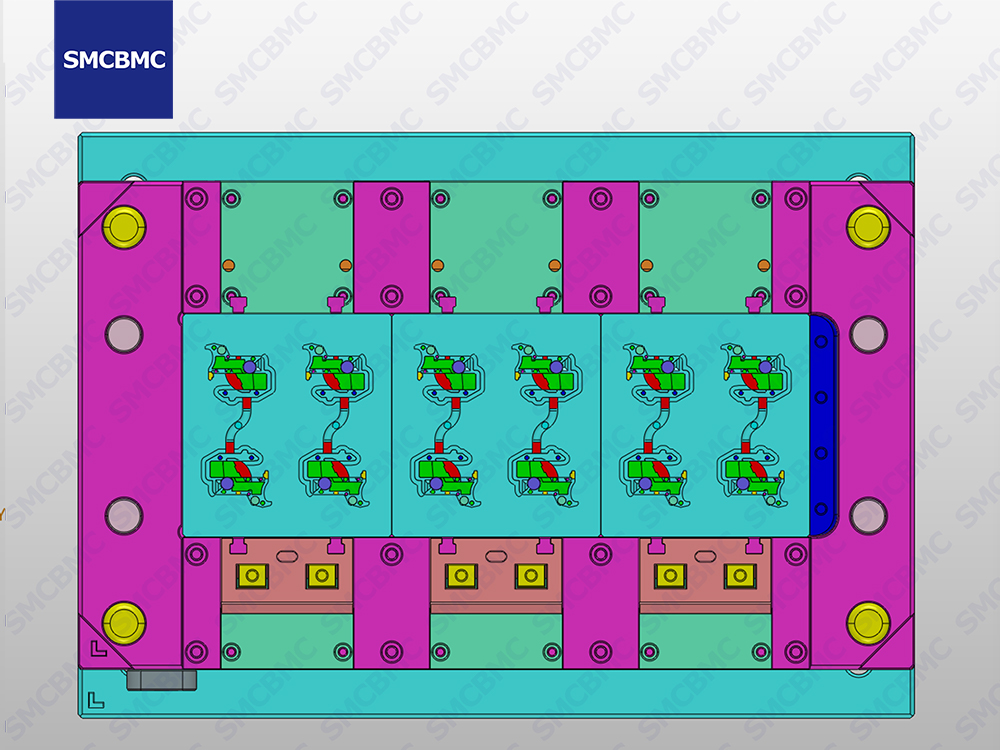

BMC molds are not passive tools—they actively shape material behavior.

An integrated approach allows mold design to be based on real rheological and curing data, including:

Runner and gate design matched to BMC viscosity

Venting systems optimized for gas release during curing

Cavity compensation based on material shrinkage behavior

Temperature zoning to ensure uniform curing

This dramatically improves first-trial success rates, reduces mold modification cycles, and stabilizes long-term production.

Even with the right material and mold, BMC performance depends on process discipline.

Integrated control enables precise optimization of:

Mold temperature uniformity (typically ±5 °C)

Pressure curves during filling and curing

Cycle time matched to curing kinetics

Demolding timing to prevent post-cure deformation

Because material, mold, and process are developed together, laboratory performance can be reliably transferred into mass production—batch after batch.

When material science, mold engineering, and molding know-how operate as a closed loop, the result is not incremental improvement—but multiplicative value:

Shorter development cycles (30–50% faster)

Lower total cost through higher yield and less rework

Stable electrical and mechanical performance

Reduced supply-chain risk and clearer responsibility

For safety-critical components such as MCB housings, motor insulation parts, transformer spacers, and rail electrical components, this integration is no longer optional—it is essential.

At Wenzhou Jintong Complete Appliances Co., Ltd., we operate as:

A BMC/SMC material developer

A precision mold designer and manufacturer

A high-consistency BMC molding supplier

By controlling the entire chain—from formulation and tooling to molding and validation—we deliver not just parts, but predictable performance and long-term reliability.

This is how advanced BMC molding should work:

one system, one logic, one accountable partner.

Wenzhou Jintong Complete Appliances Co., Ltd. specializes in high-performance BMC/SMC thermosetting composites, precision mold design, and molded component manufacturing.

We serve electrical, motor, rail transit,new energy, and high-end industrial applications worldwide.